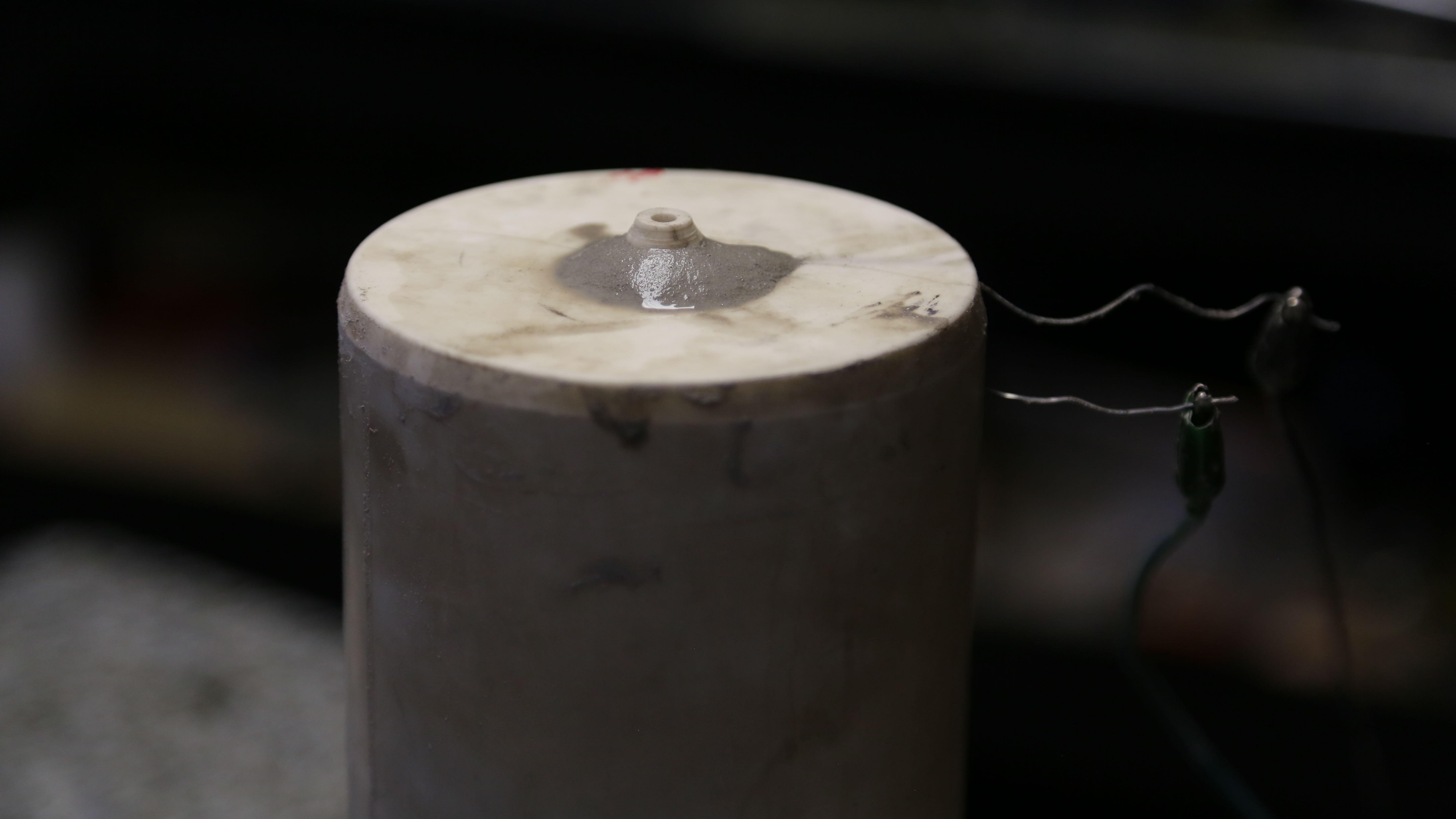

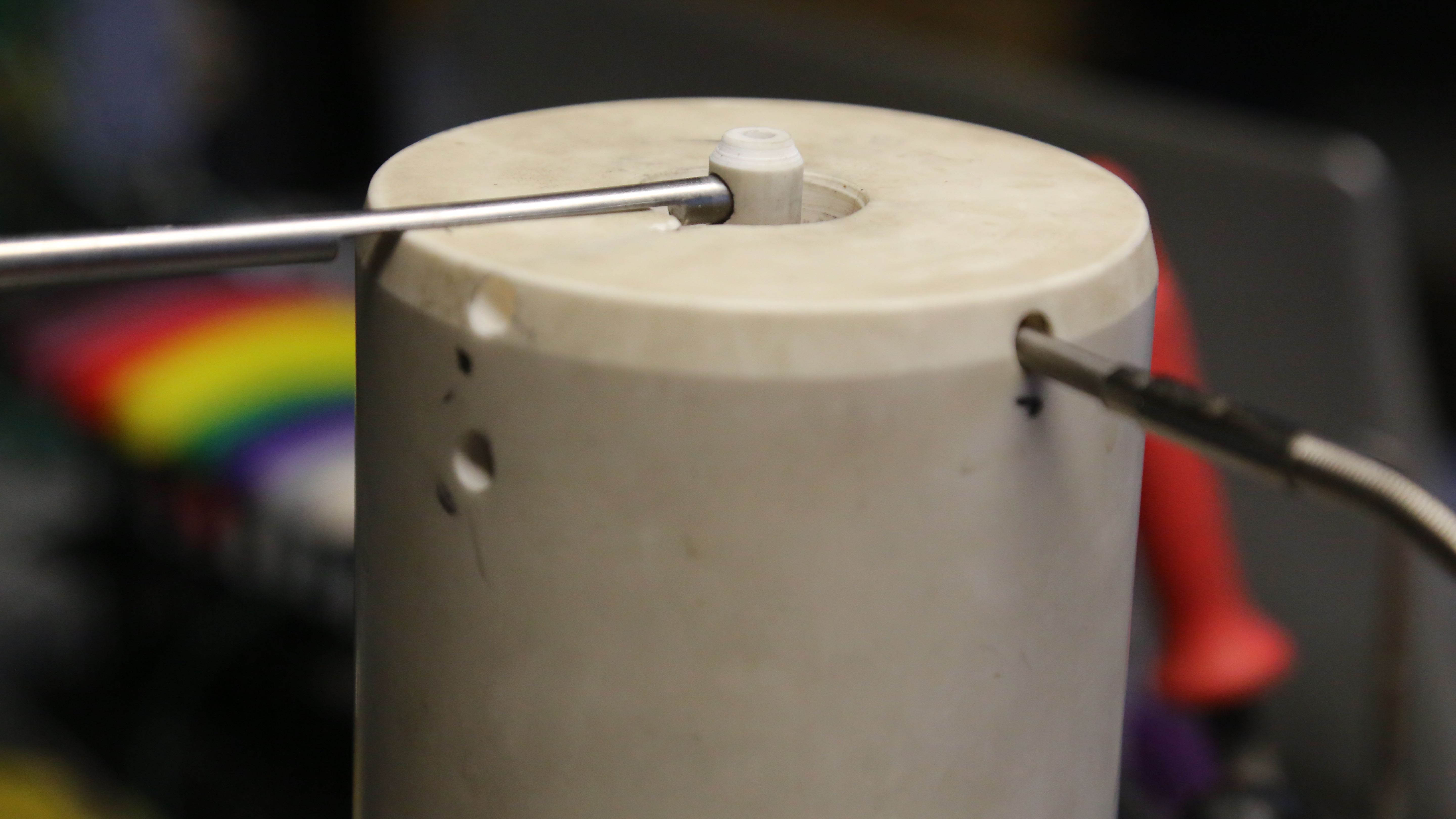

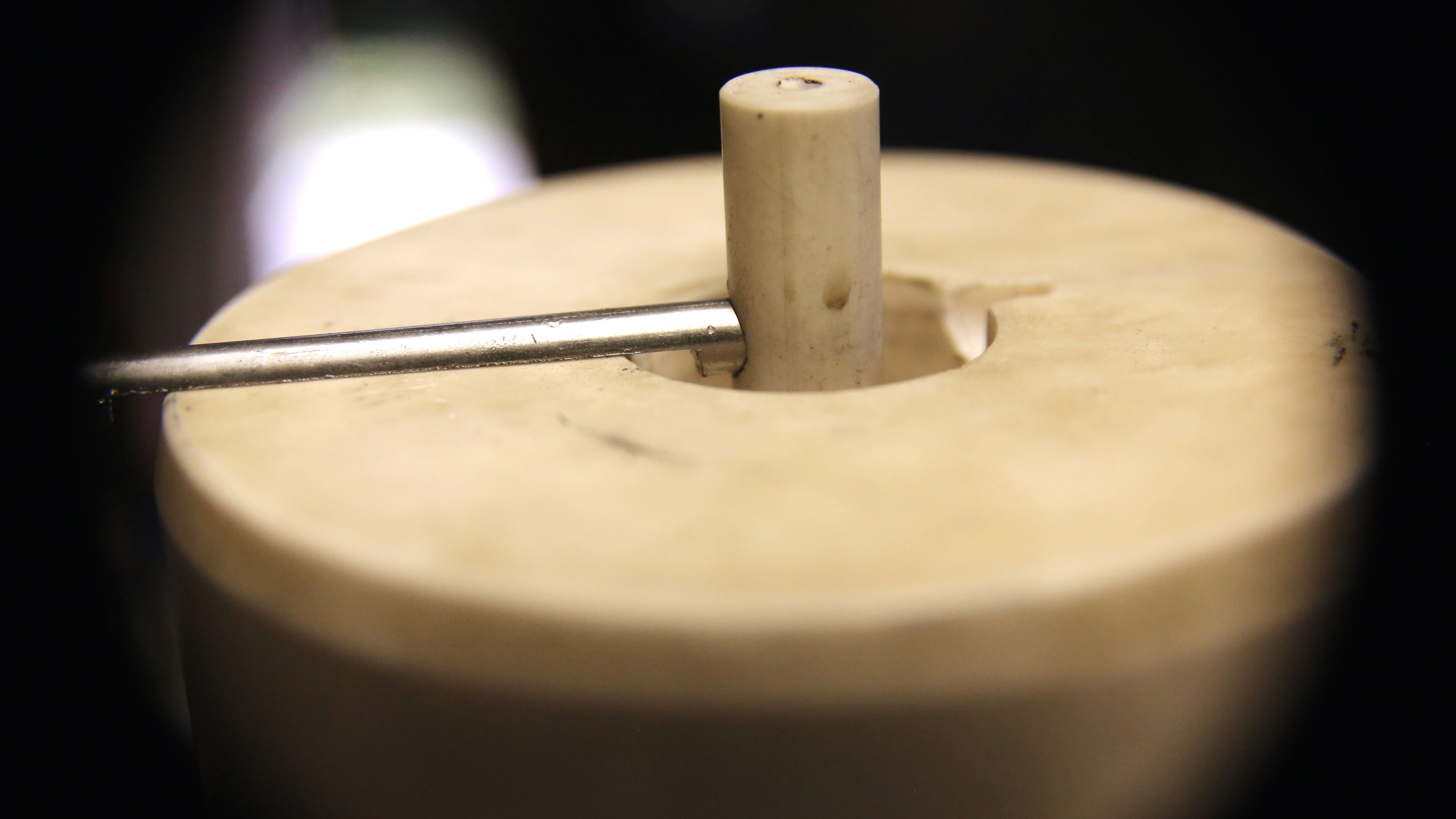

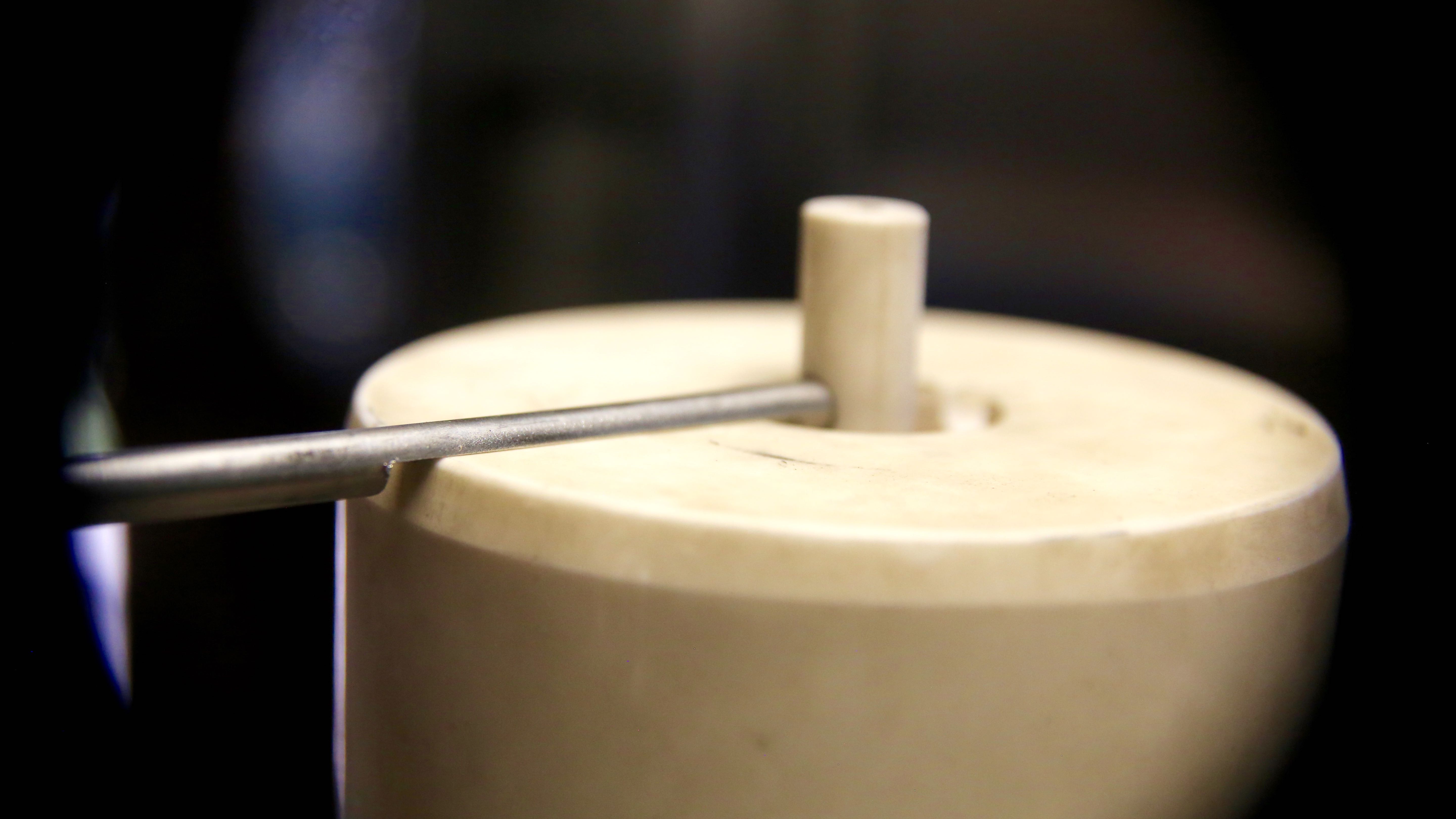

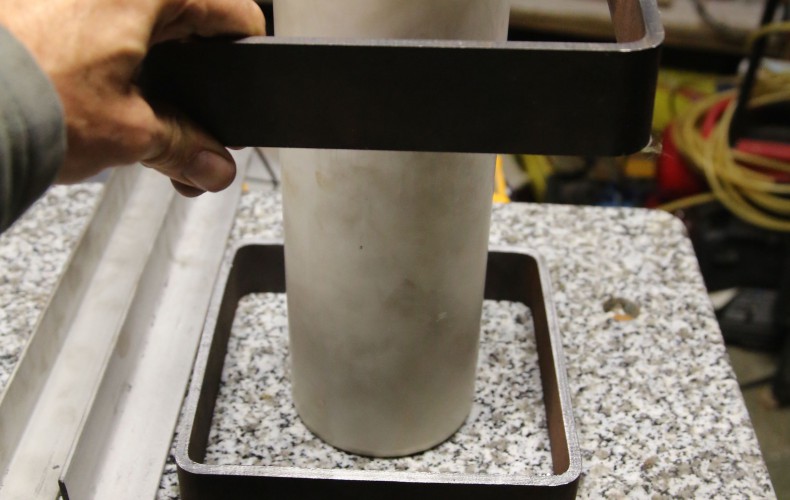

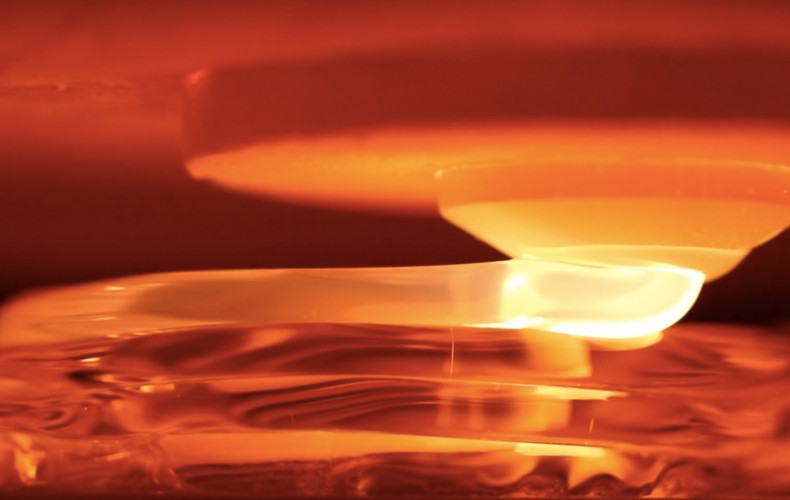

Our first nozzle heater coil attempt failed miserably. The refractory selected for the task was far too course and we were unable to fill the nozzle cavity properly. So when it heated up, the heater coil sagged and shorted out. But – we did learn from our mistake(s)!

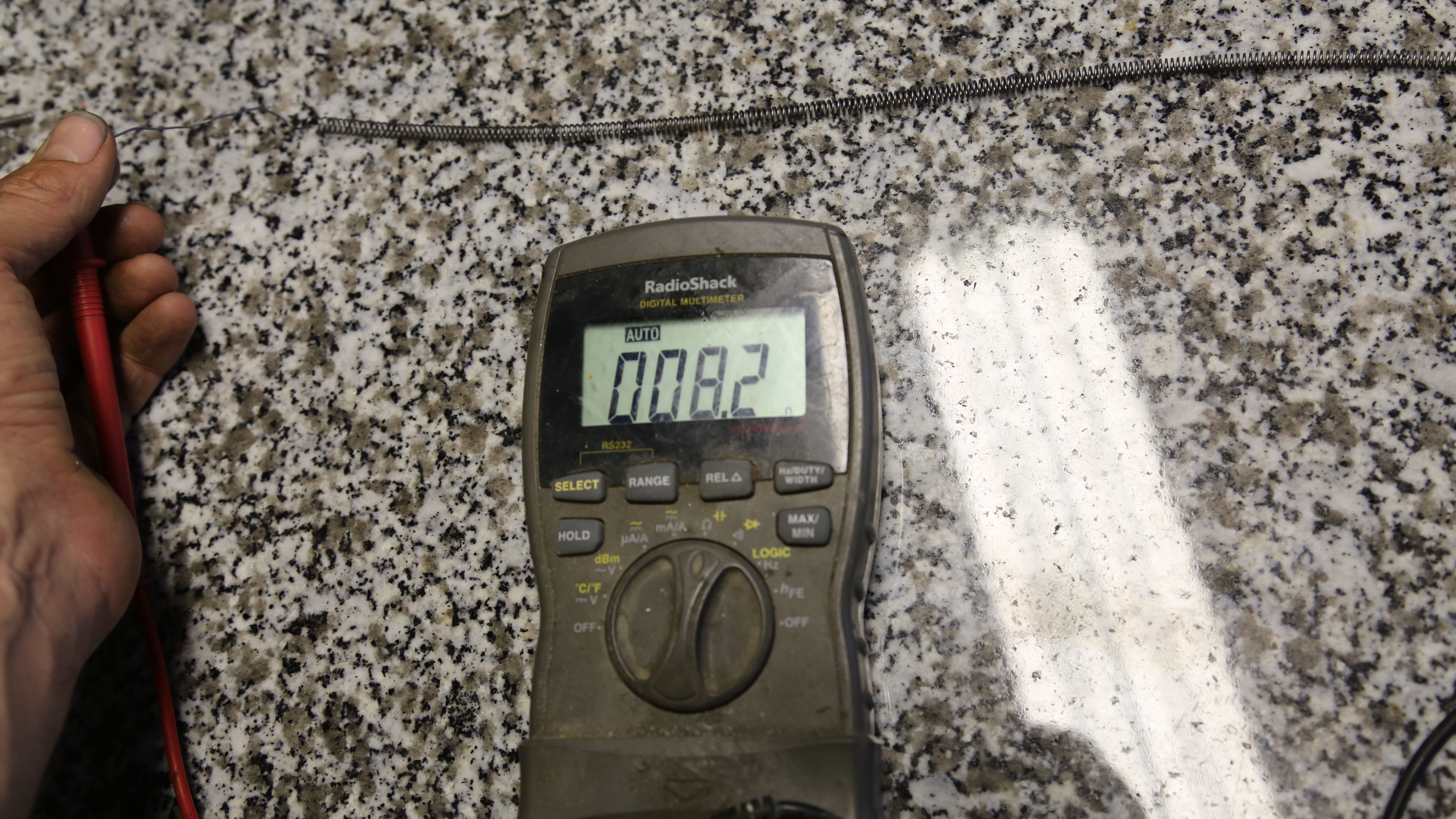

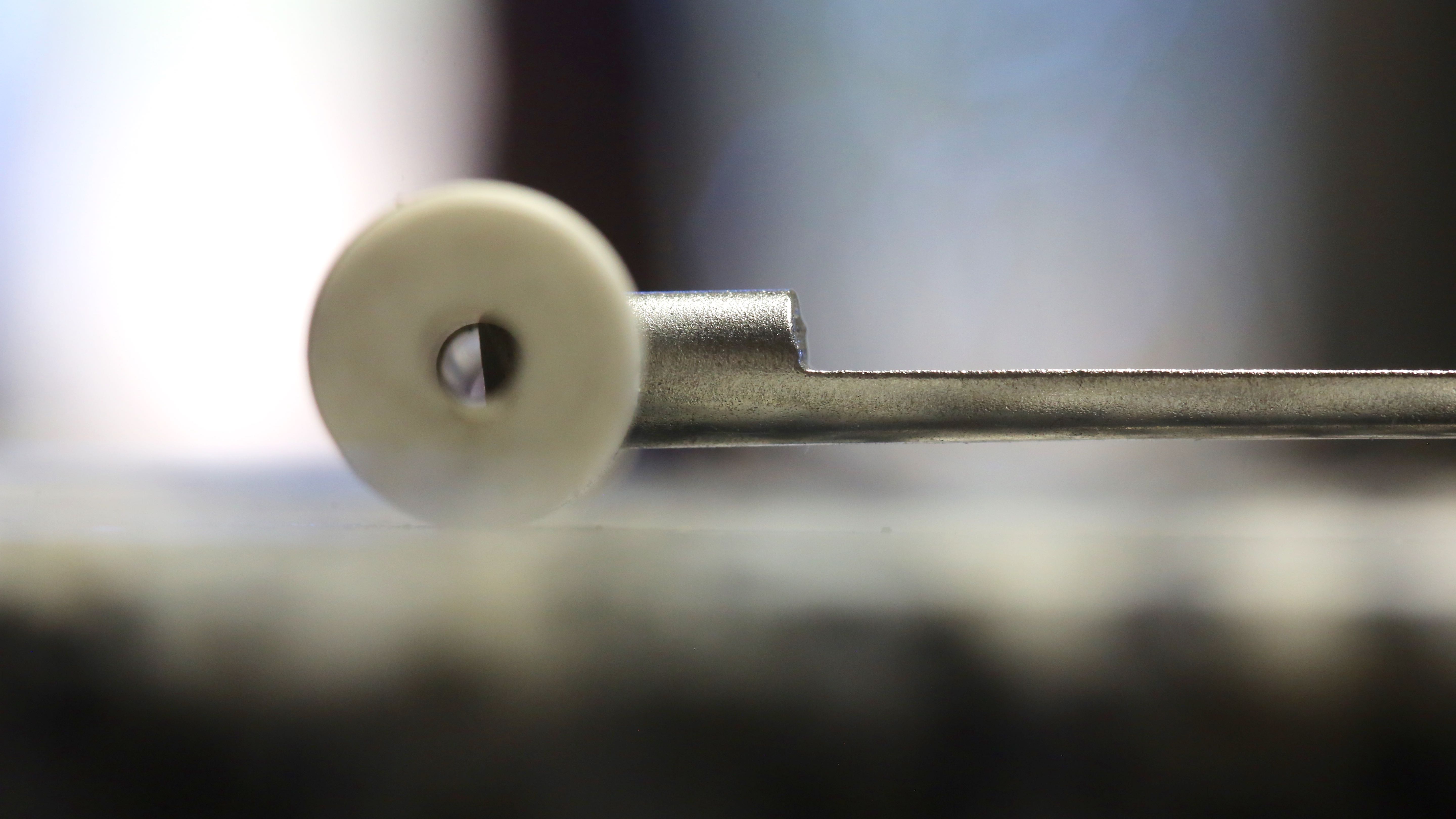

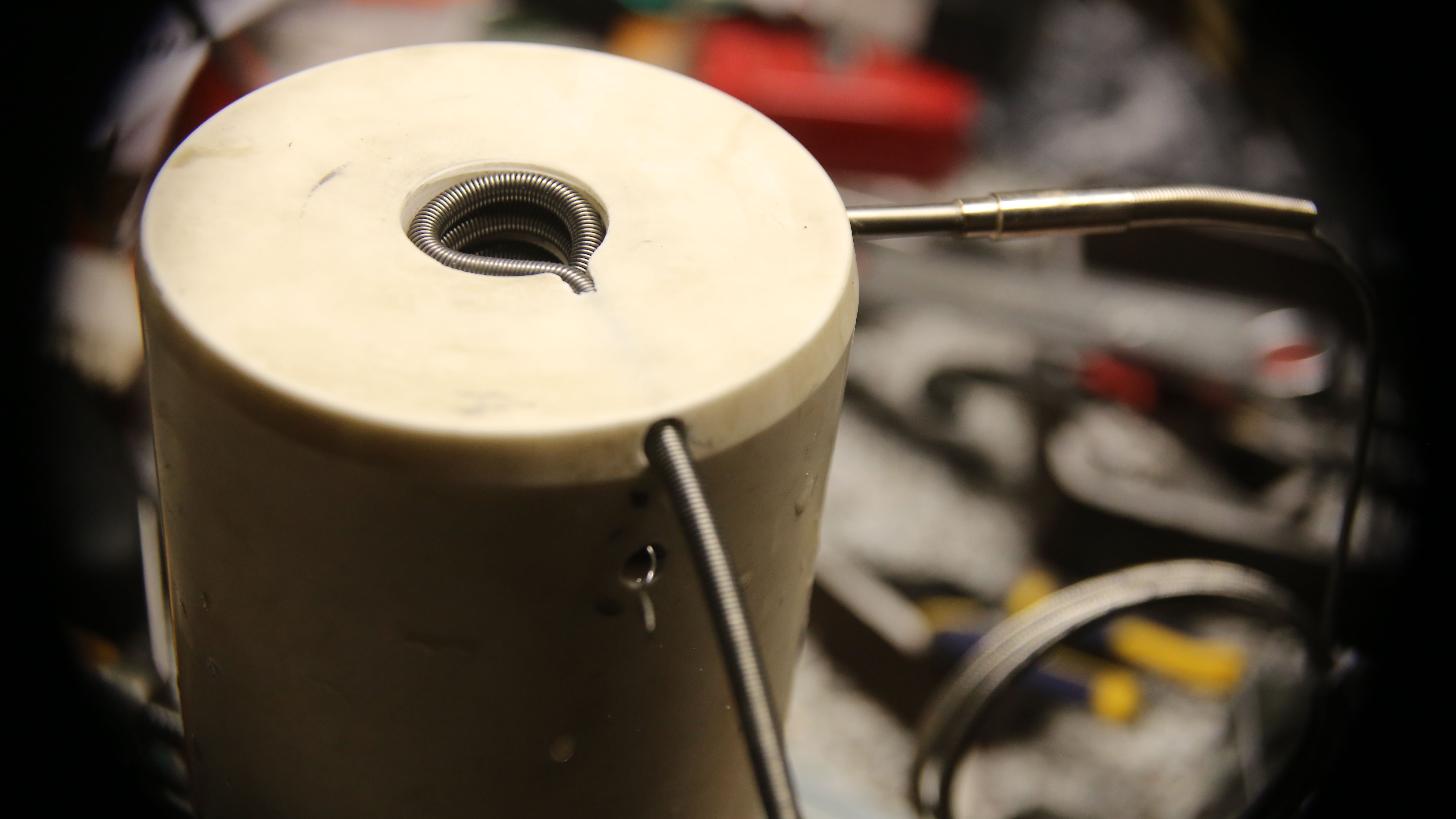

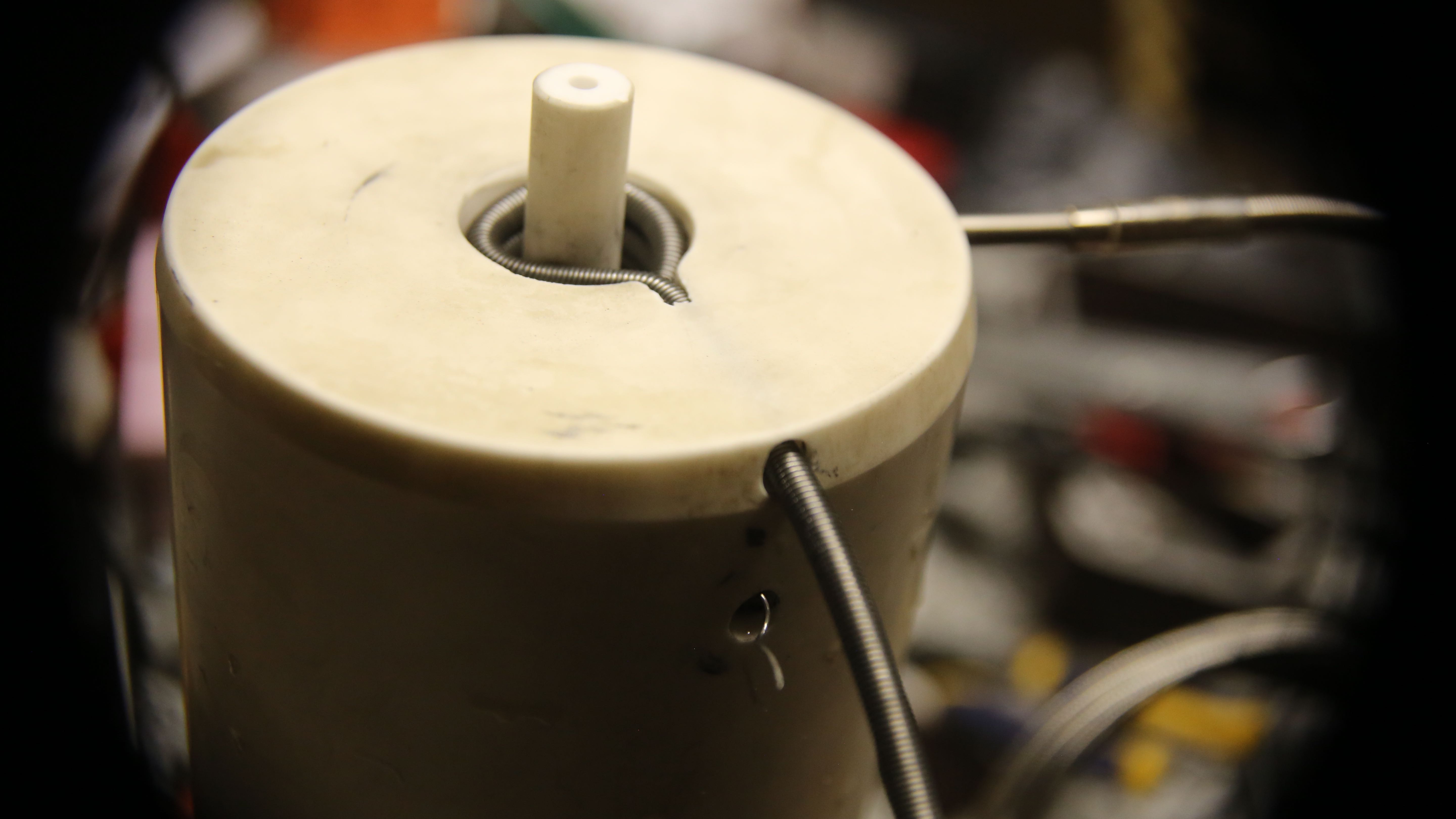

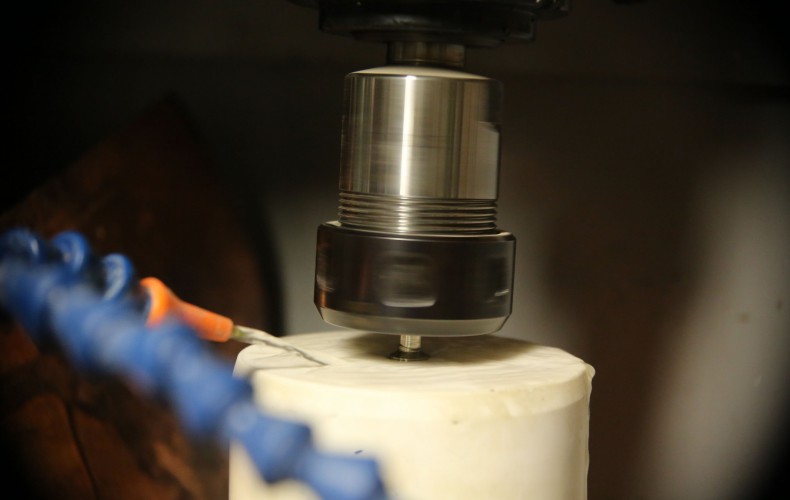

One missing step was to measure the resistance of the heating wire before it is hidden from view. This lets us keep an “eye” on the coil even when its buried in refractory. So if we get the resistance readings after packing refractory, we know for sure that the coil has not shorted out. The first coil didn’t short out, but it wasn’t packed satisfactorily.

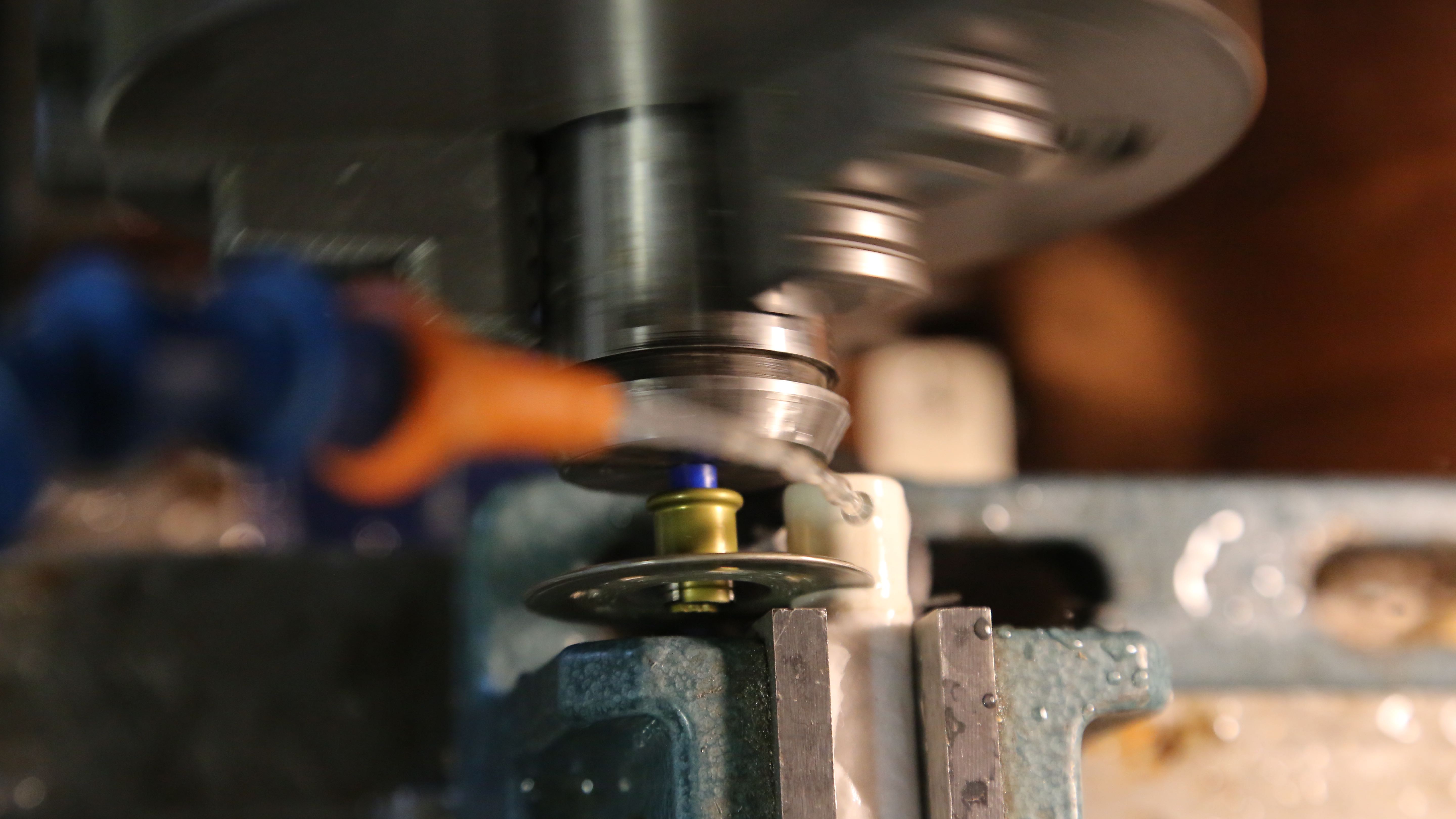

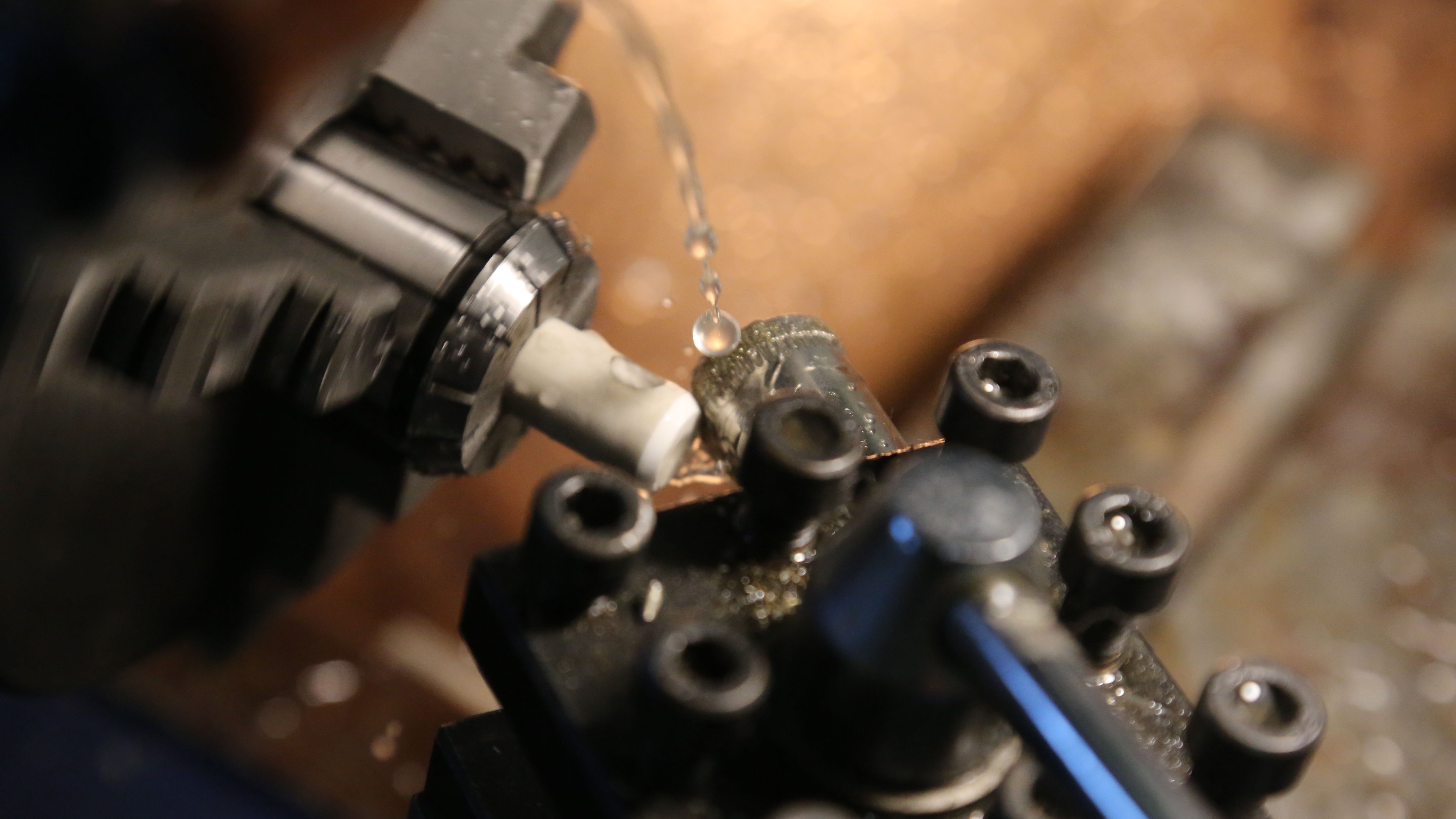

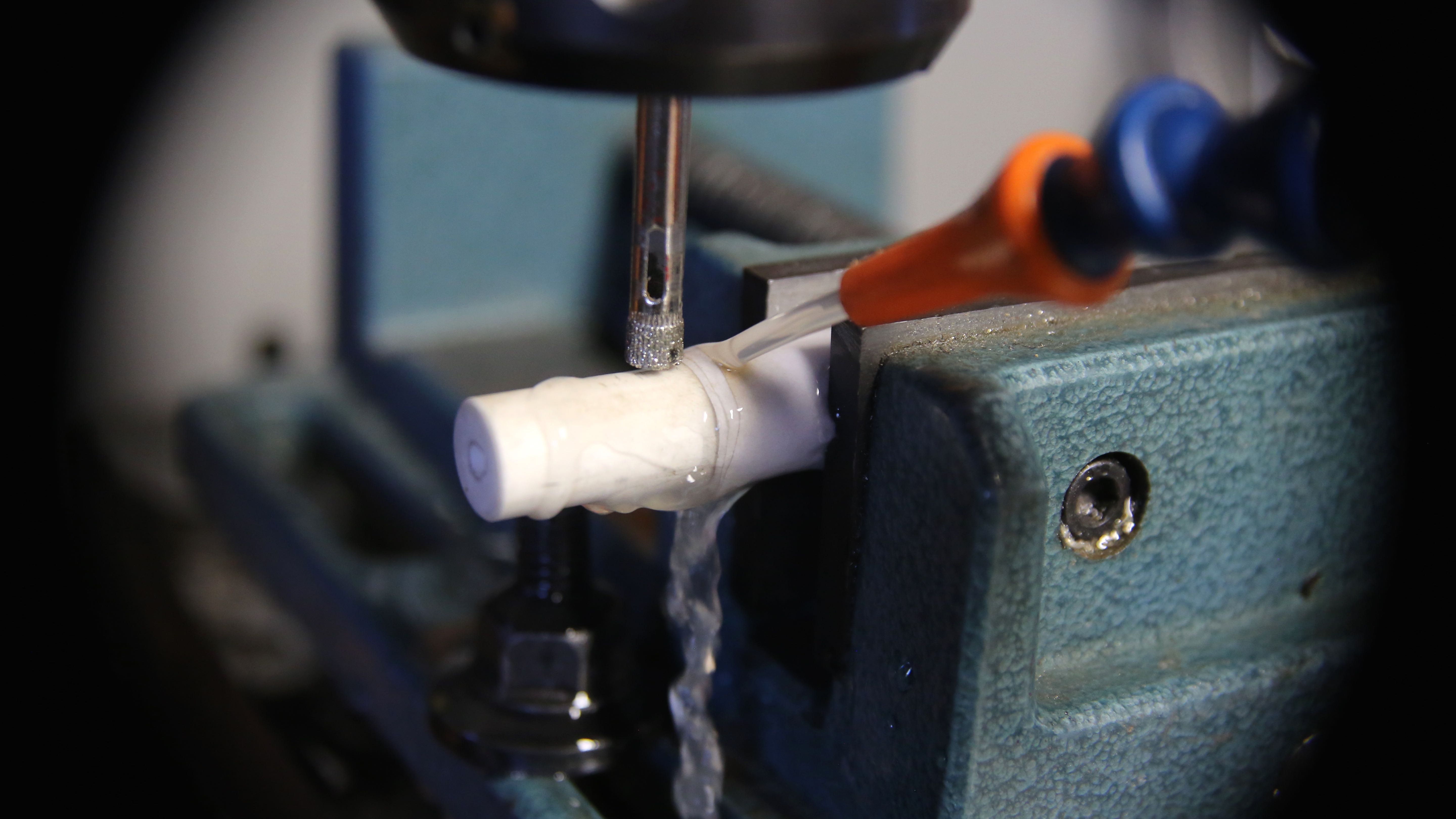

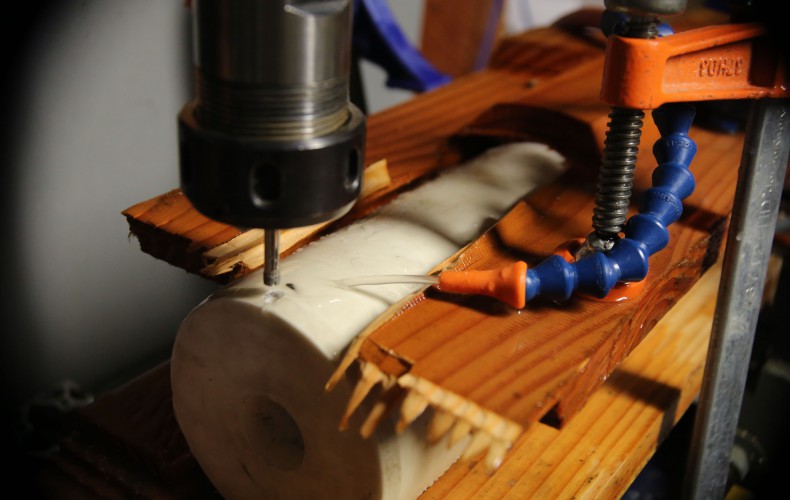

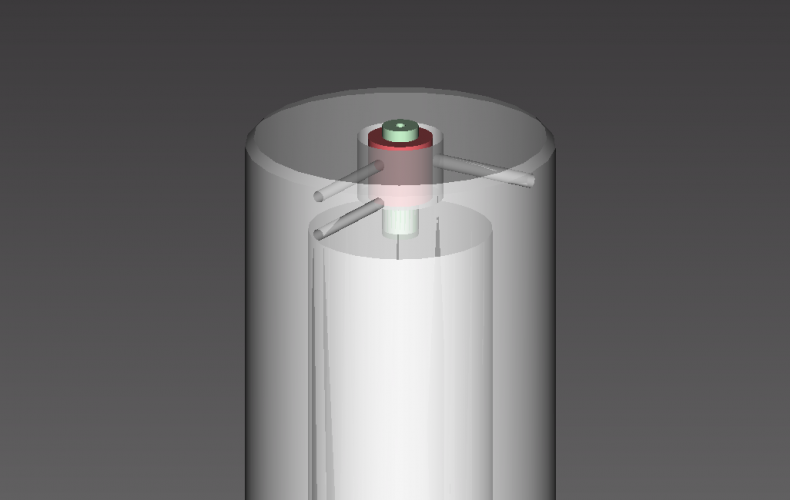

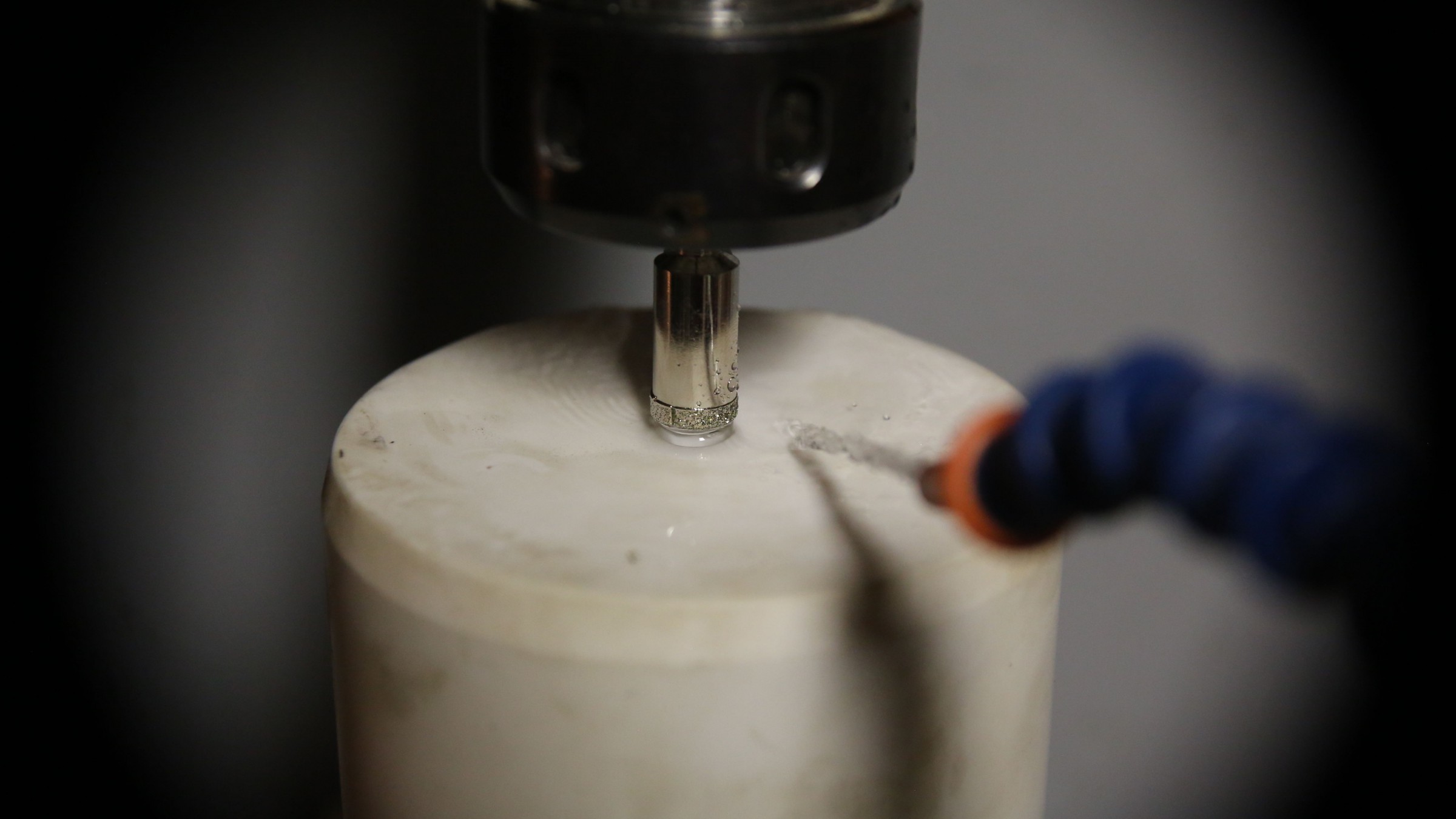

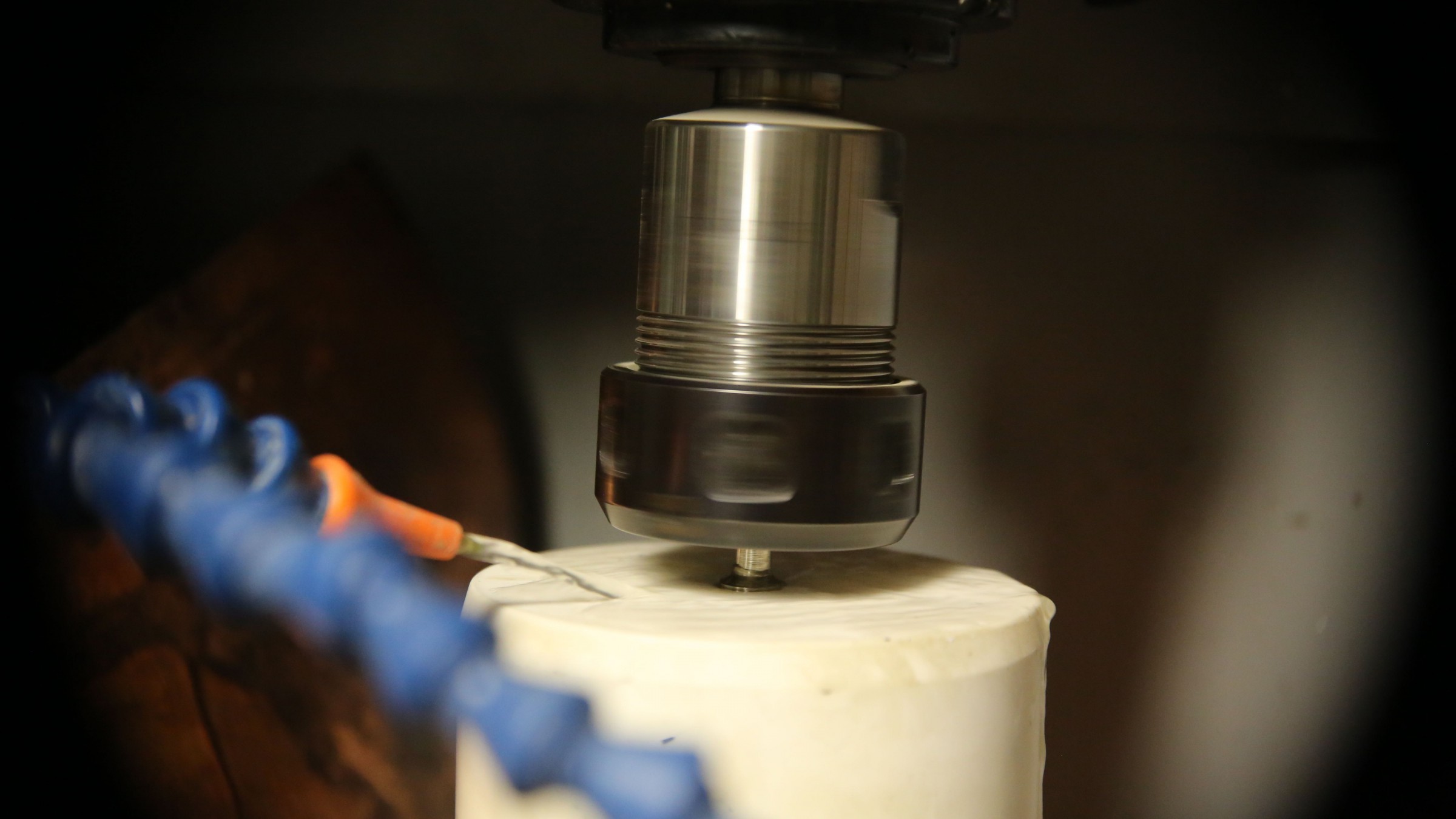

Another thing we learned is; it was difficult to pack the coil in place. So to help to that end, we decided to pre-pack the heater coil (after stretching of course). Between the proper refractory and the pre-packing we are confident this second attempt will work.