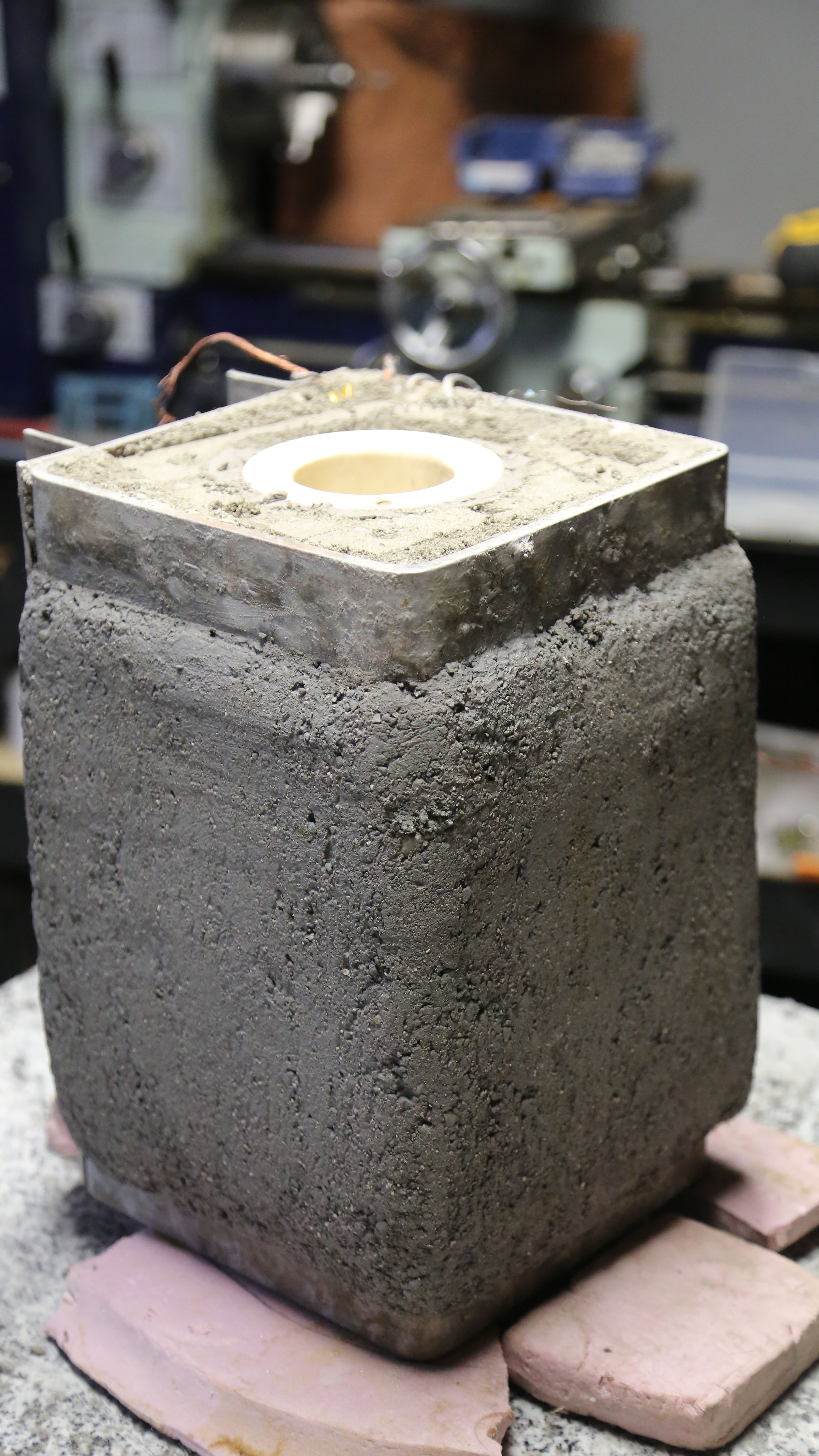

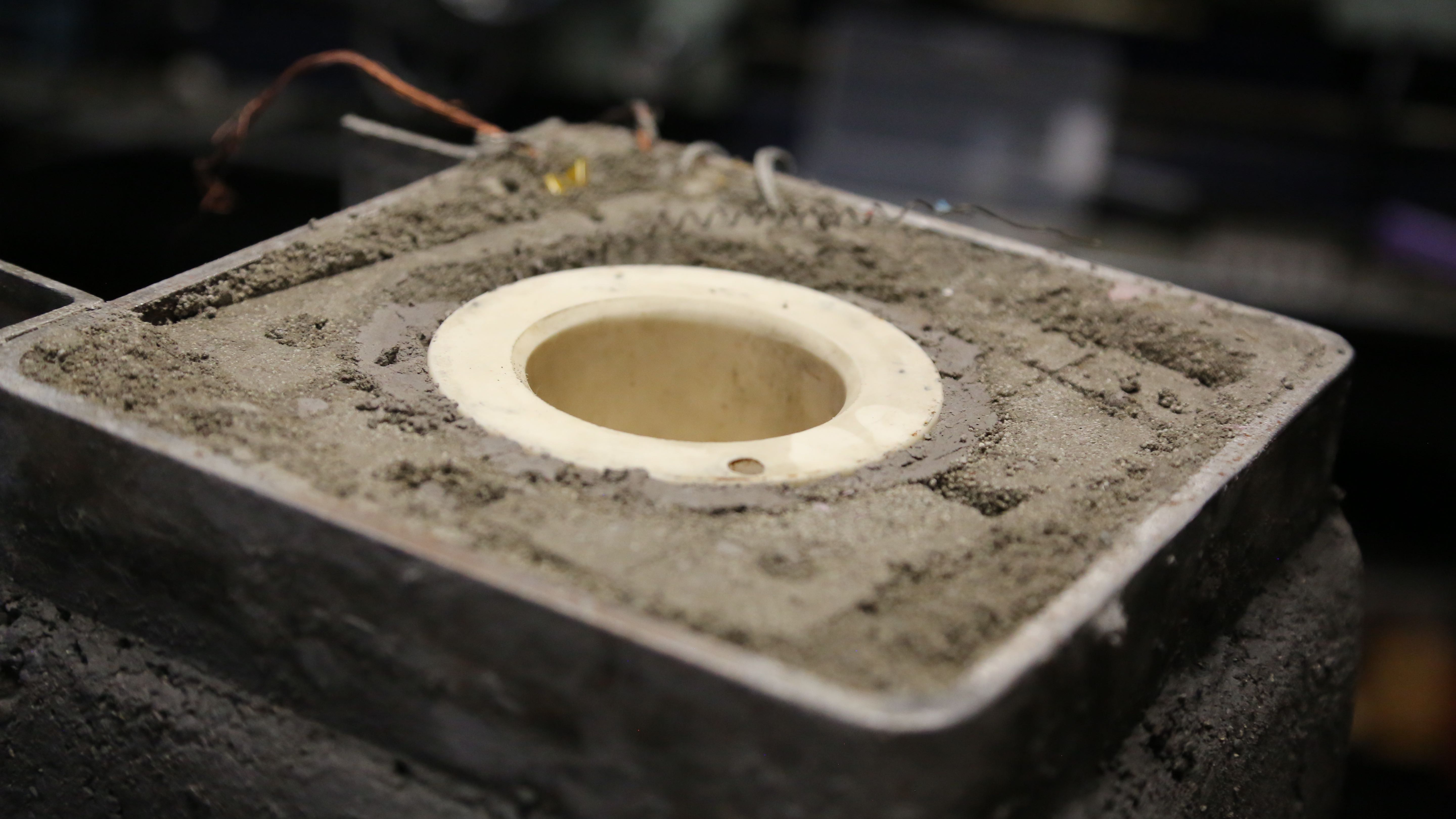

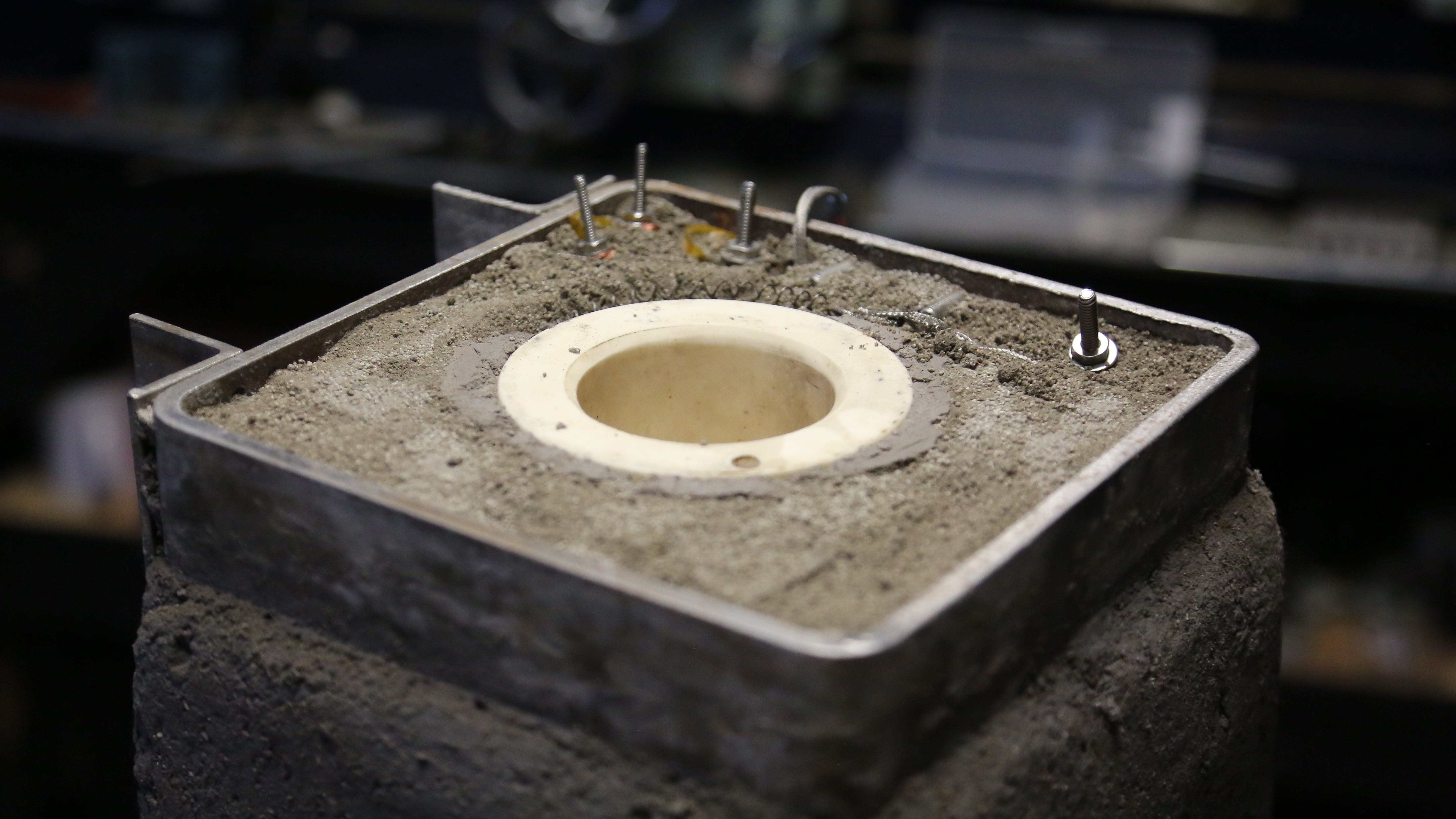

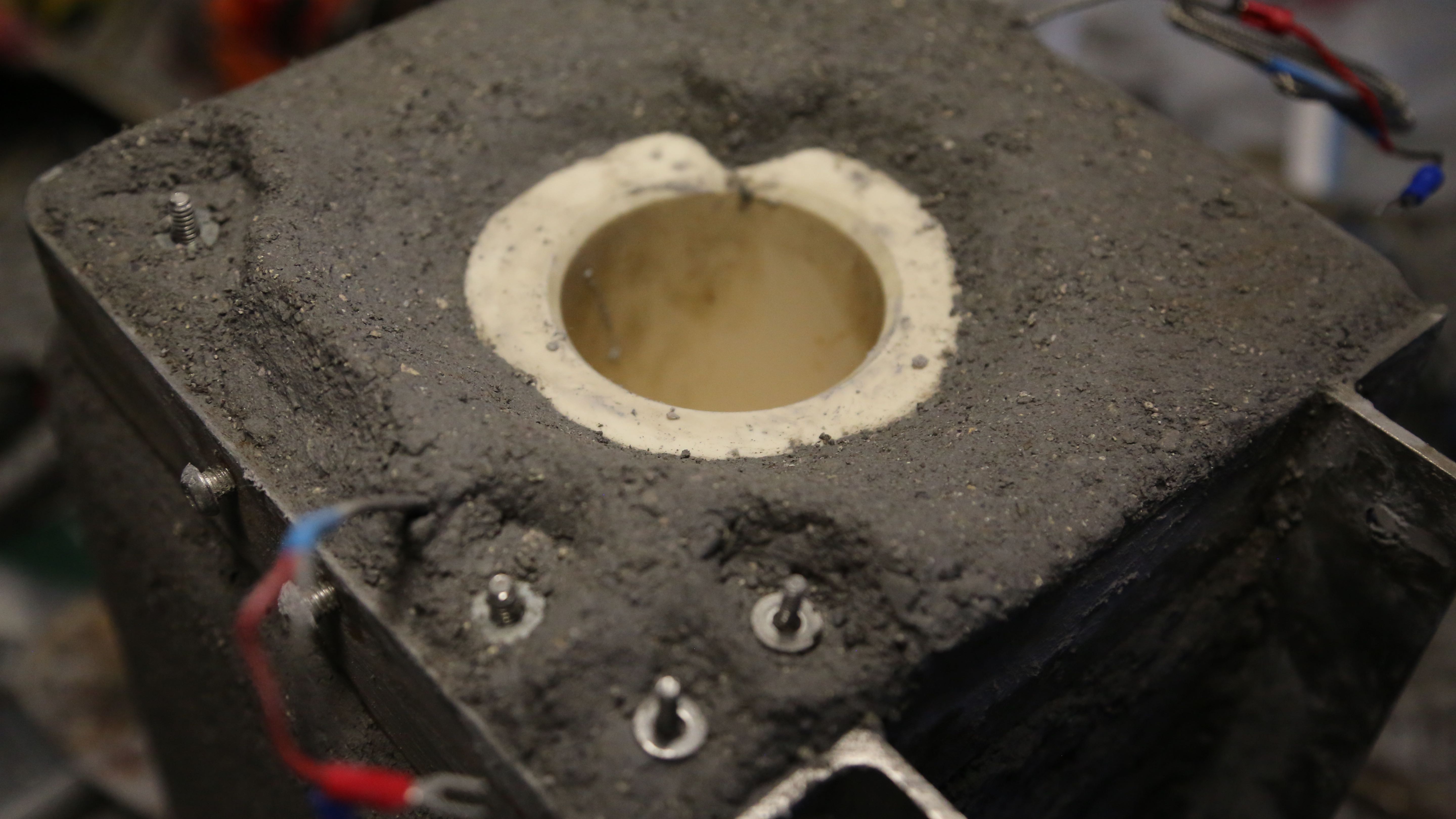

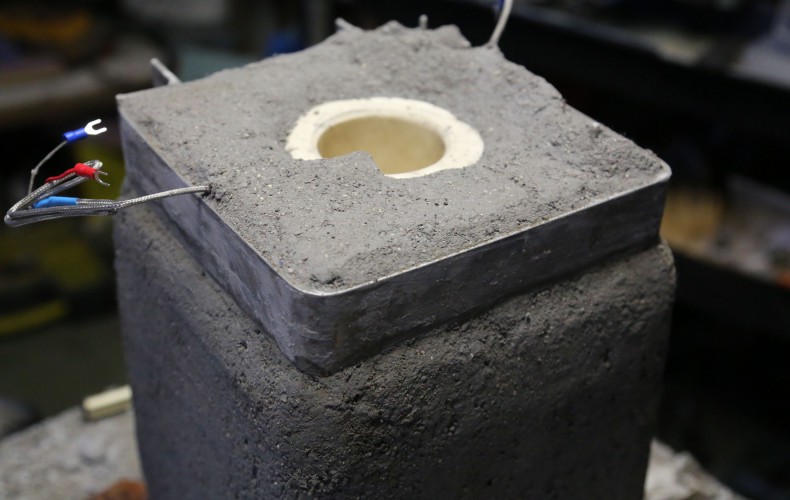

One last chapter before we can begin our crucible cart’s dryout schedule: the top. We need a bomber top to handle ladling of molten glass blobs into the crucible as well as way to fix the loose electrical terminals. The insulating refractory won’t cut it in these departments so its time for some more 3000F rated refractory to coat on top.

After its fired we can get it mounted to the machine and should be showtime!

Leave a Reply