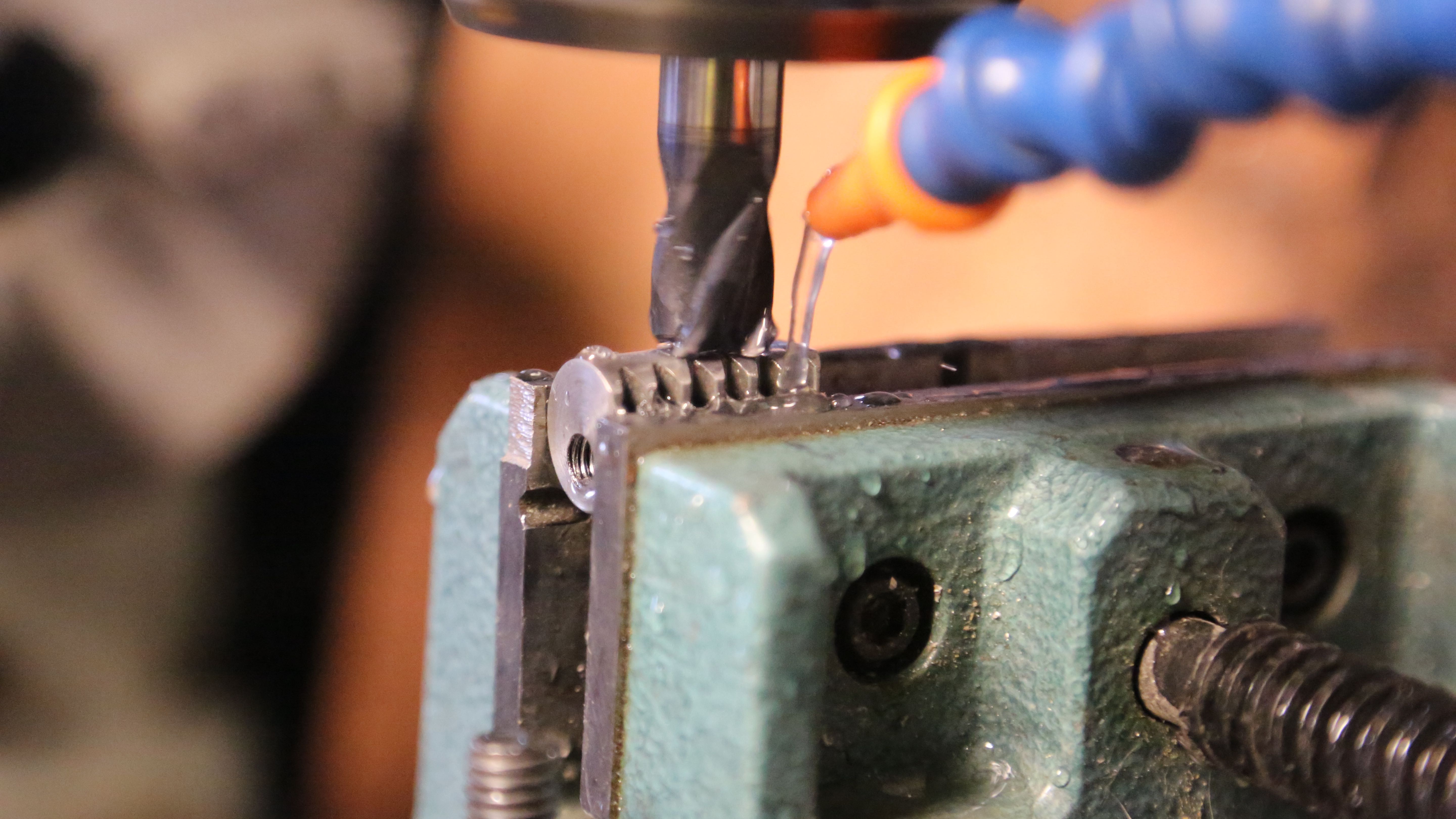

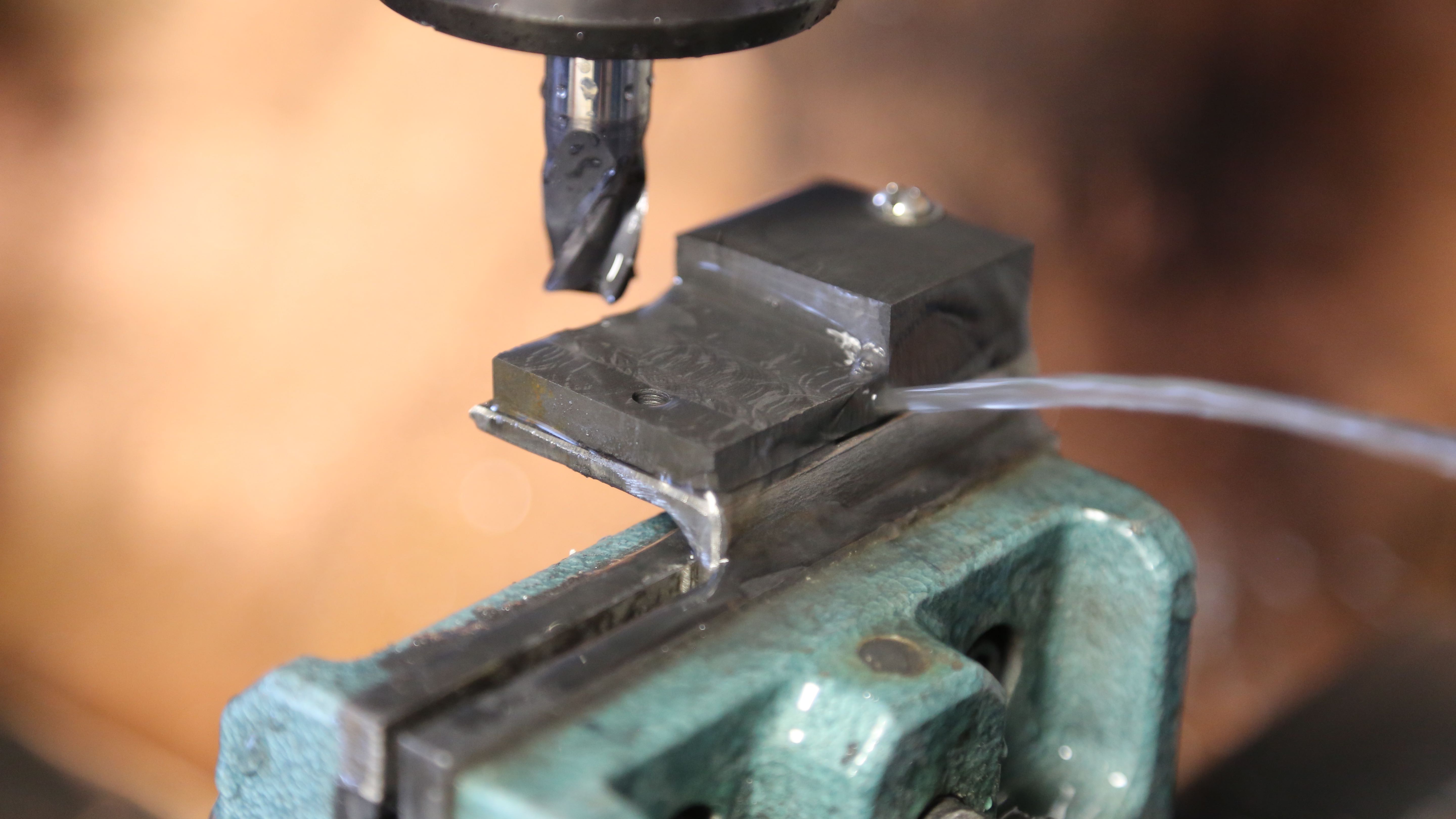

In order to control our stainless steel nozzle actuator from a more reasonable room temperature, where standard stepper motors merrily step to and fro, we needed to transfer the power to outside our 800F print chamber. For that purpose it seemed that good old rack and pinion was the ticket.

Being able to actively control the nozzle should allow us much greater control (it can actively restrict the flow rate), allow us to print any form without restriction (other than support restrictions inherent to the FDM process), and we think it should be able to print molten metals (aluminum, copper, etc) in a similar fashion as glass.

Leave a Reply