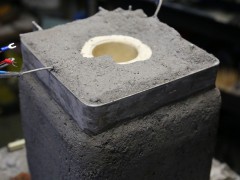

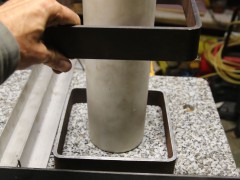

We now have the print chamber finished and installed on our massive machine. The chamber will be operated at a toasty 800F during printing glass (it will be put to use for pizza firing undoubtedly after a days run) that allows the inter-printed layers to adhere (and at optical quality), grow without warping and or cracking and to anneal so a printed piece doesn’t self-implode at some time in the future.

Leave a Reply