As much as I would prefer to only report success we are learning a lot which means of course means making some mistakes along the way.

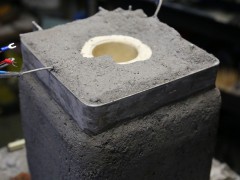

The first design of our glass melting furnace relied on a 2KW wire heater. After installing the wire we found that it only deliver 1.3KW at best. In addition, burying the metal wire in castable refractory was likely a fatal mistake, because I now suspect that the wire needs to be able contract and expand each operating cycle. Even if it didn’t there is a chance that at operating temperatures the refractory (which is a good insulator at room temperature) could have become conducive at working temps — potentially shorting out the entire heater coil.

In addition, even if the coil had operated at 2KW for any length of time (ignoring the above) it would have taken a long time to heat up and likely struggle to maintain the desired temperatures. In other words, it was vastly underpowered.

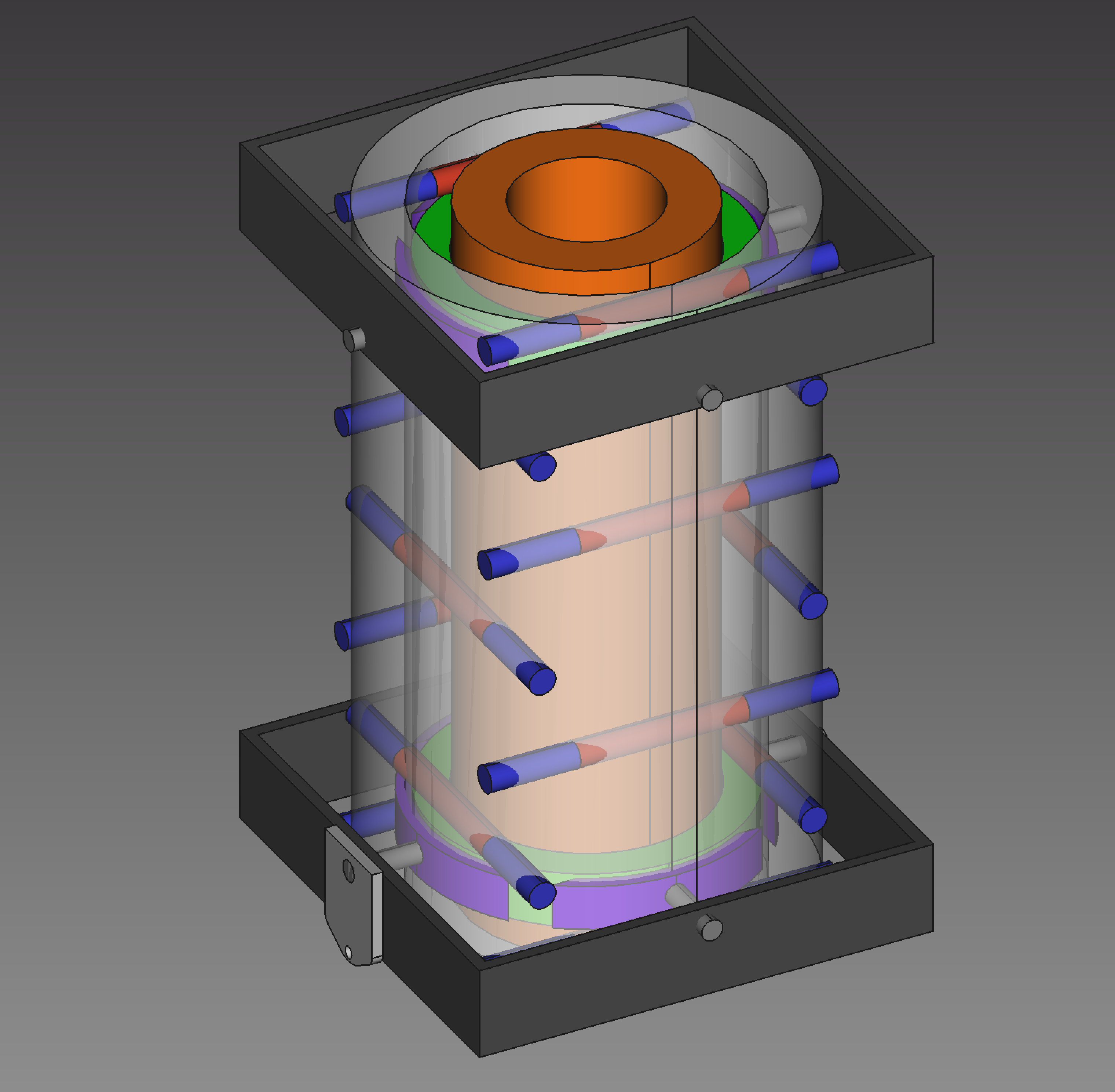

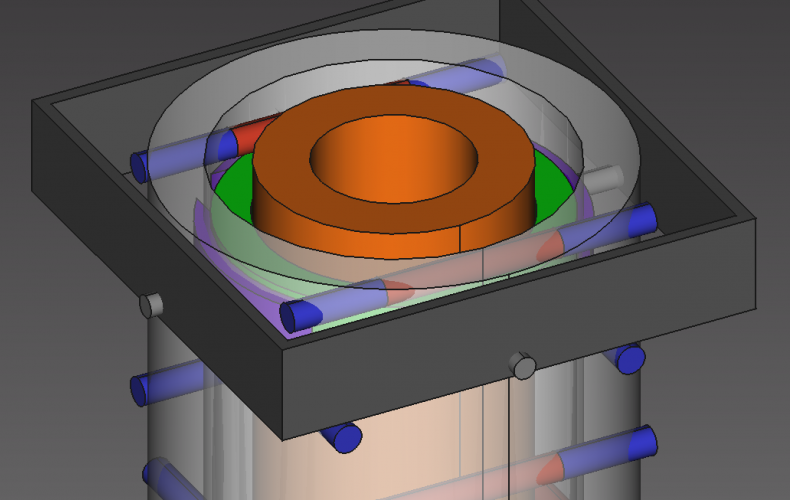

The new design is based a 7KW system comprised of Silicon Carbide (SiC) heating elements (ED shape). In addition to heating up rapidly, the new setup will allow us to operate continuously 1500C. This will allow us to print borosilicate (Pyrex®) and possibly interesting things like (fired) ceramics and de-composed granite (that is what the “dirt” we are sitting on top of is mostly comprised of).

So while it has been a bit of a misstep, it will only be for the better. Our set of custom SiC rods are currently being fabricated in China and will hopefully ship to us this week. All other aspects our massive printer have been tried and verified to work. More soon.

Leave a Reply