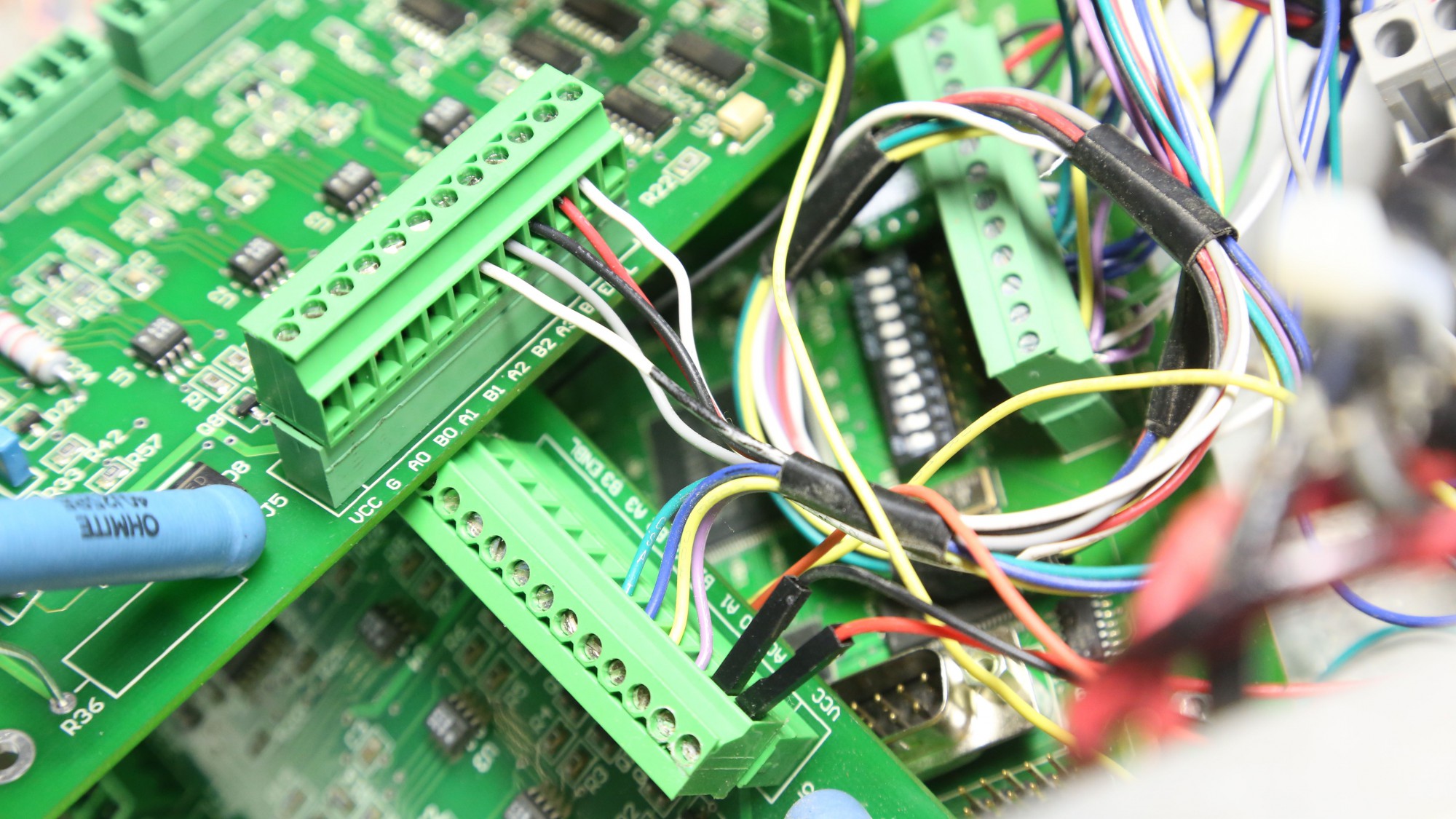

Evidently in my last post I was reckless enough to challenge Murphy by taunting: “Looks like we should be printing our first glass tomorrow!”. It turns out that a couple of seemingly insignificant mistakes met for one big 7,000 watt ZAP setting us back weeks. Our machine’s (once perfectly working) sensitive motion controller took way more than it was designed for cooking components all the way up to the PCI card in the computer. We are mostly back to operation now with three of our four axes on the machine fully operational (X, Z and A). We have Y narrowed down but at the time it is not operational yet.

The “insulation” of our wire made unintentional contact with our 240 volt 30-amp service, but only because we wanted to see how the crucible furnace behaved before insulating it. That said, we have learned from our mistake and as a result the machine is much safer for it. Now for critical things we say “that shouldn’t happen” we have it covered at least once or twice it the event it does happen!

Leave a Reply