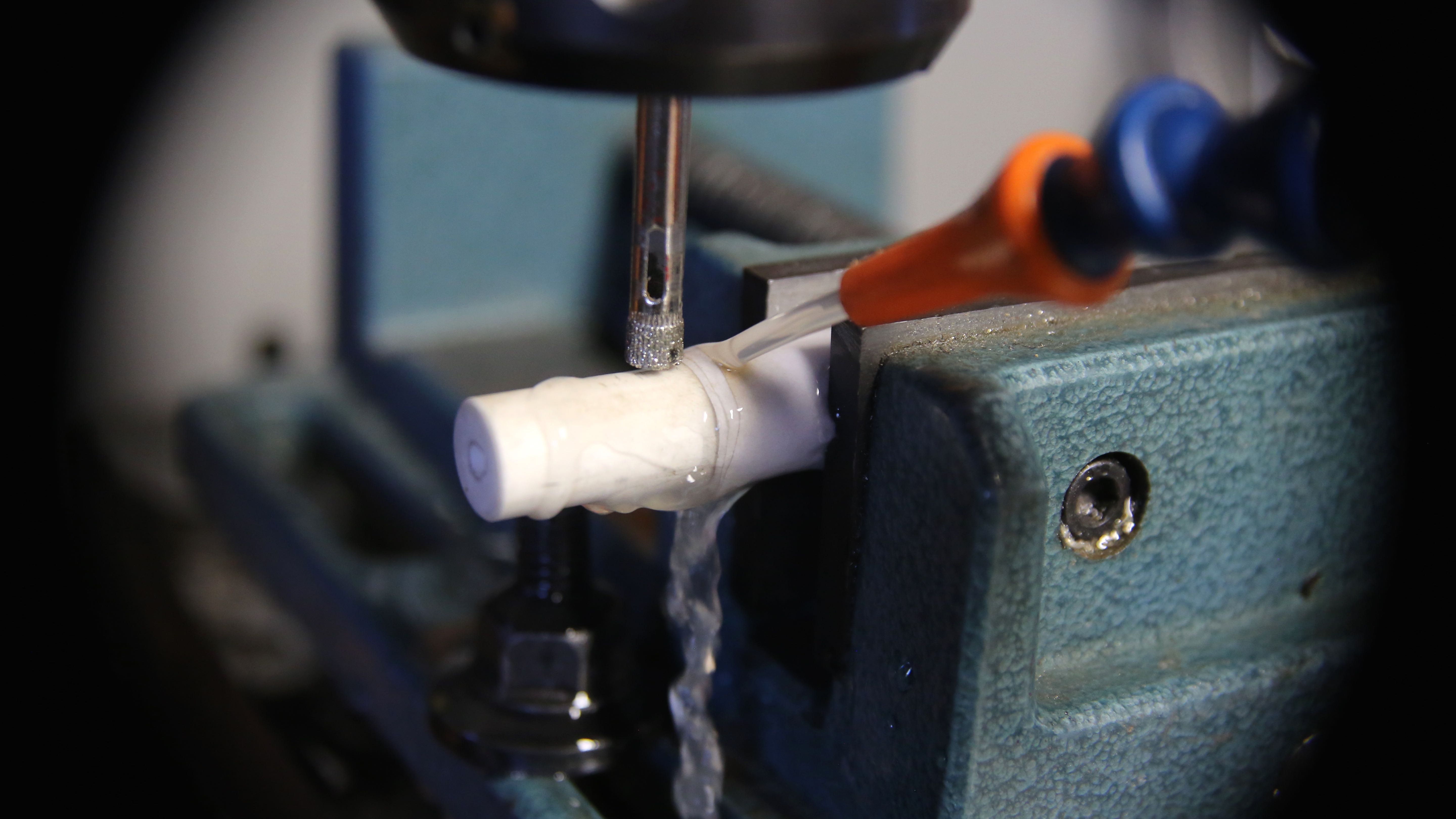

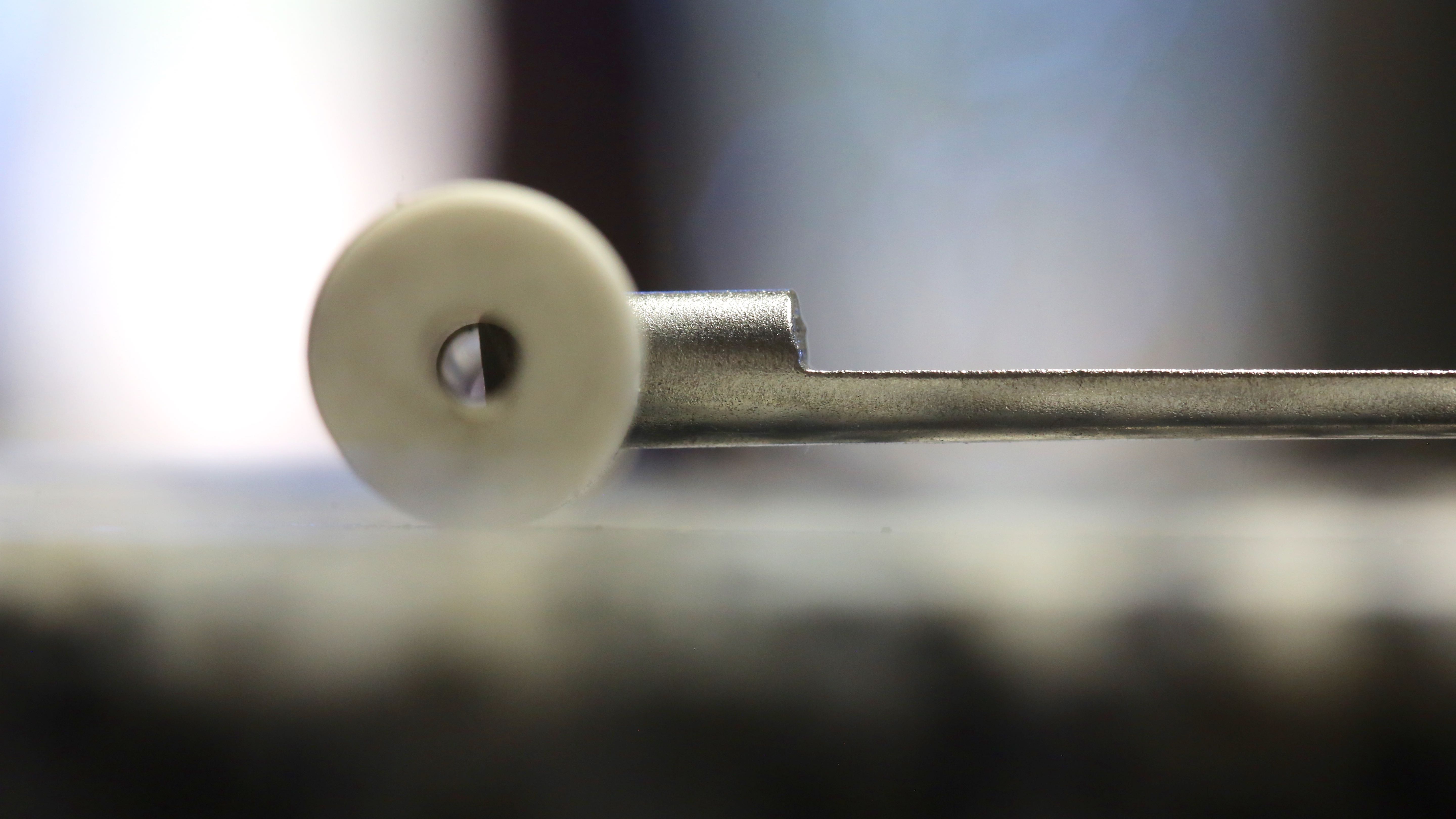

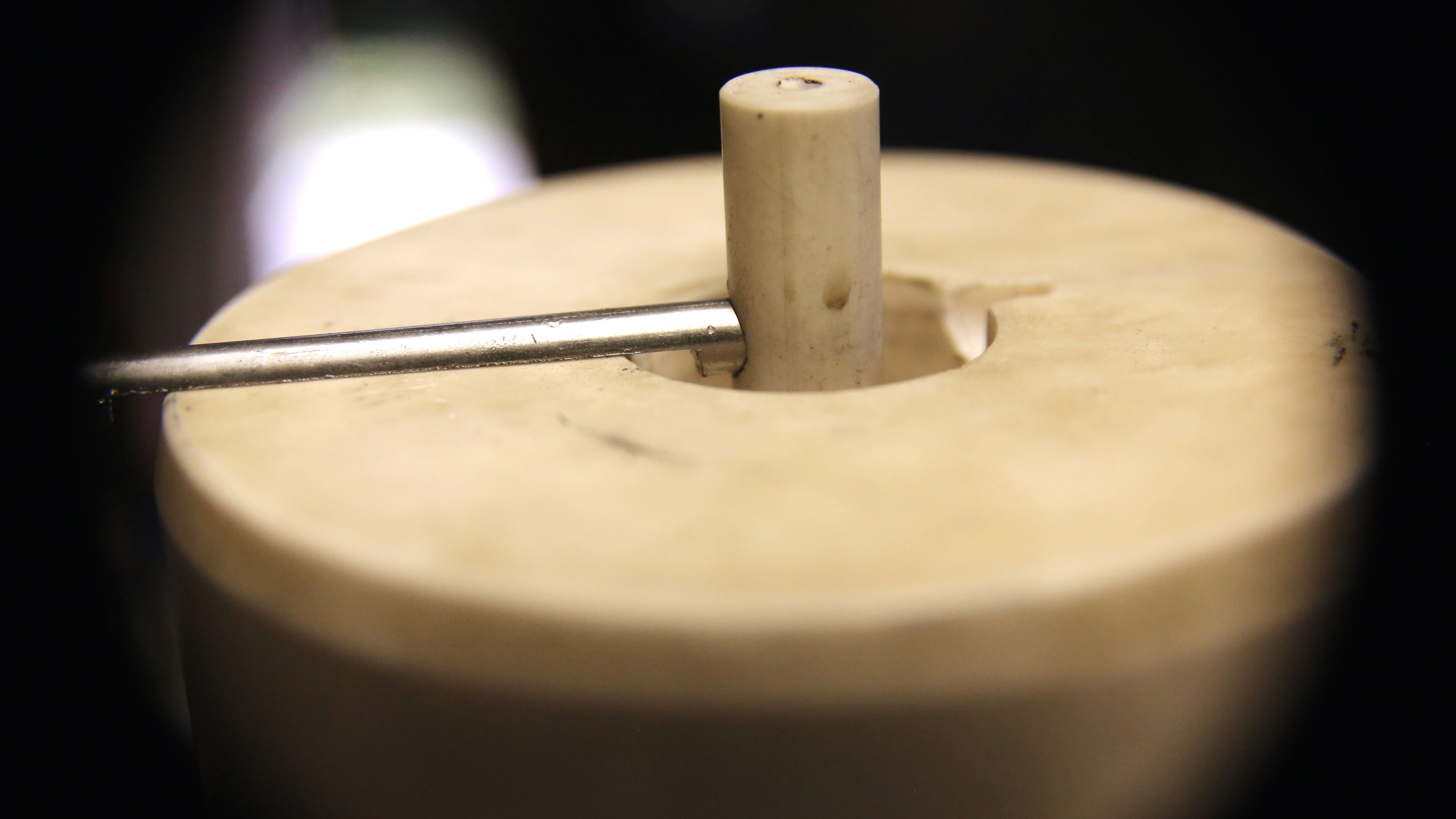

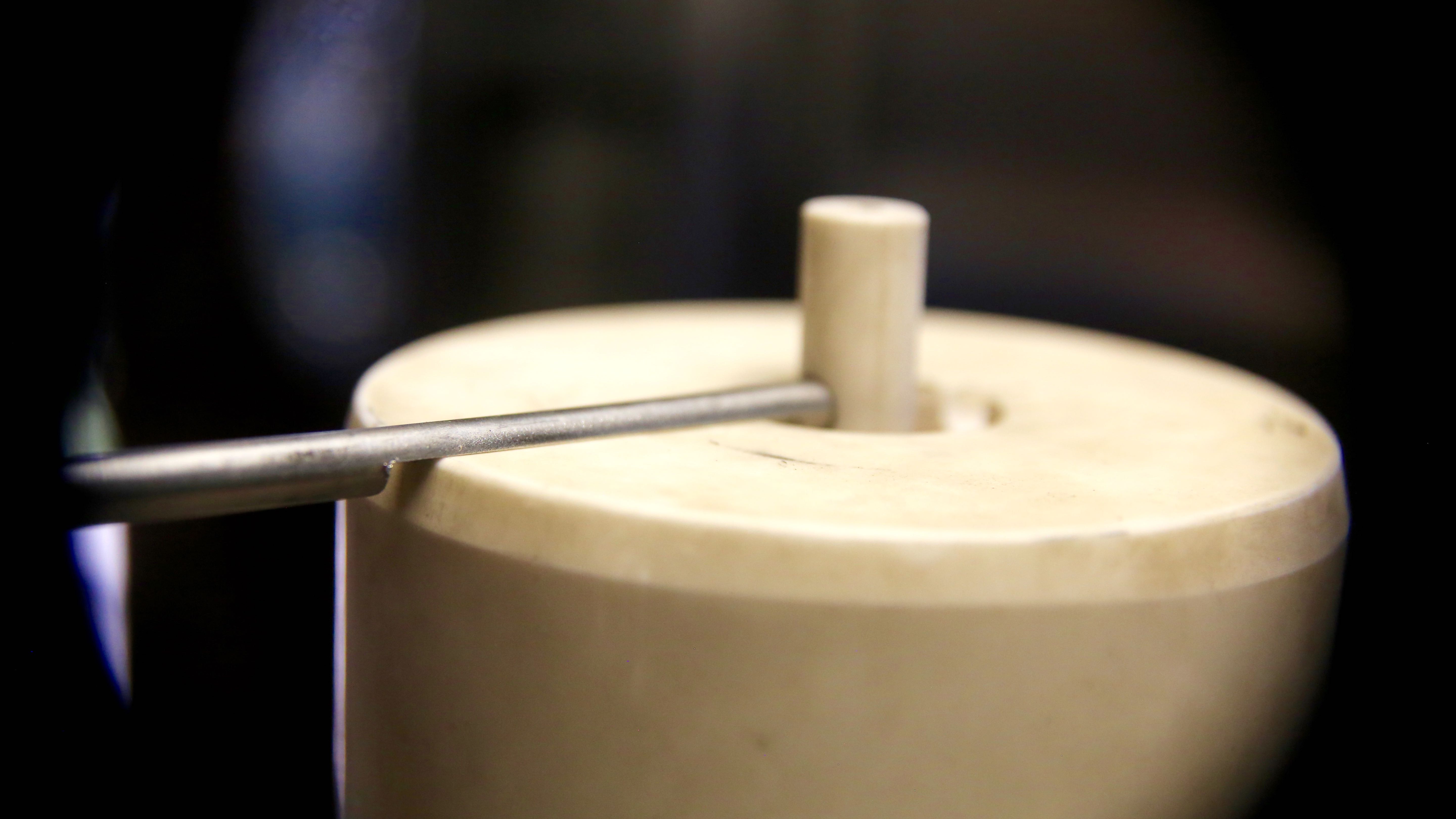

One thing we really wanted from day one is to be able to actuate the nozzle. It will allow for much more complex pieces to be printed beyond single wall items (such as vases) than the glass printer as described by MIT. There are some ideas presented by the Glass Lab, though this is our stab at the task.

As eager as we are to get the nozzle glowing yellow; we took the time to put it in now. We are quite pleased with the outcome so far (to be tested of course). We wonder if aluminum and copper will be printable with this setup?!?

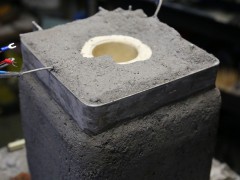

The main reason we bit the bullet now is the crucible assembly will be much more fragile after its all been fired, so we needed to do it now if it is to be done with our initial setup.

Leave a Reply