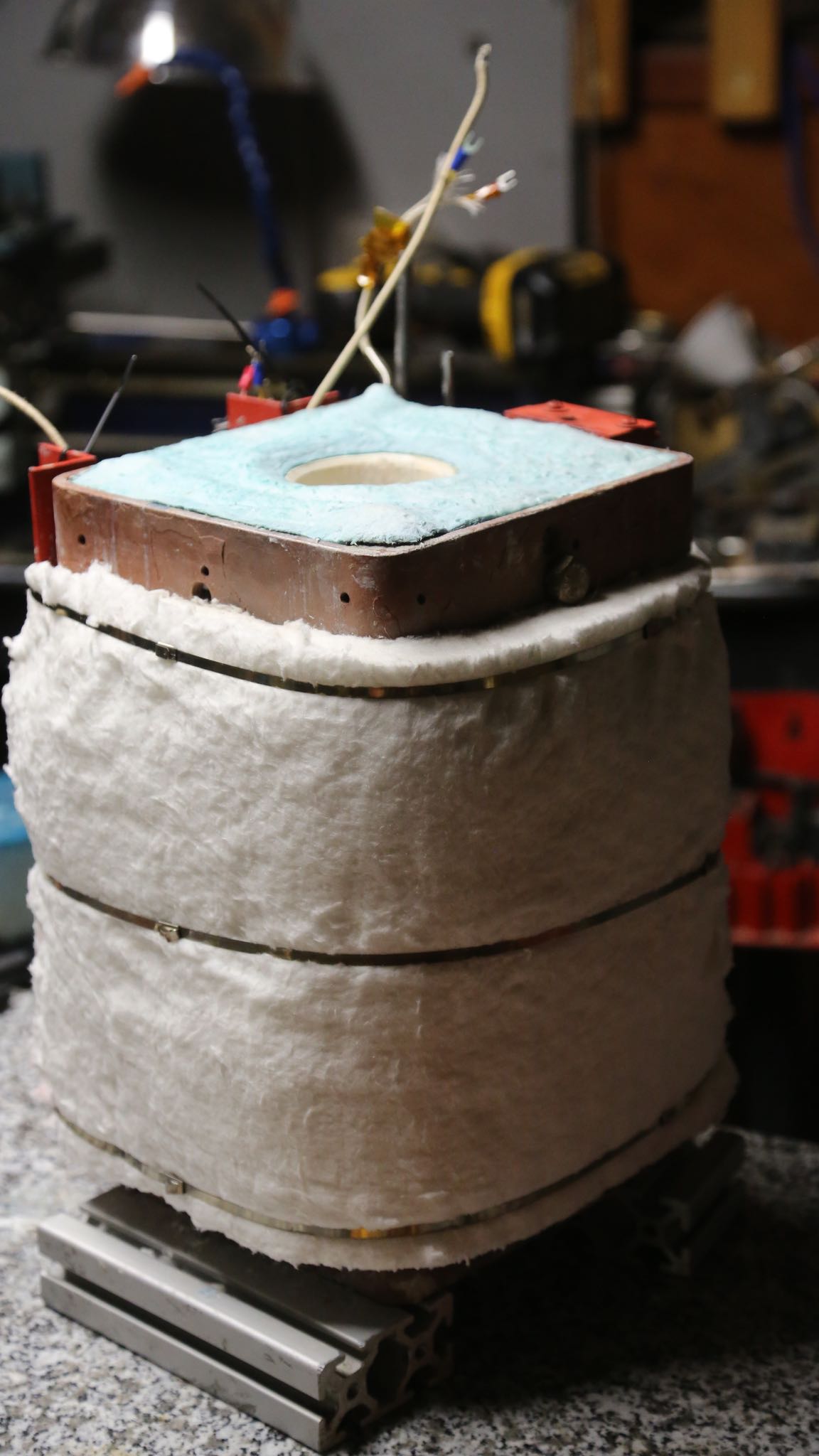

This post has been a while in the making; my apologies. It turns out that it is one thing to run an electric load at room temperature, and quite another altogether to operate in the confines of a super compact, 2000F furnace that itself is intended to operate inside a toasty 800F furnace – continuously. In other words; the wiring to service our SiC heater rods was vastly underrated for its operating conditions. With sorrow it became clear that we had to strip down the whole furnace and rewire each and every rod. For our last attempt we ran 8 strands of 18 gauge stainless steel wire. Since oxidization is our enemy, we went with solid 6-gauge (or better) stainless steel rod. It is worth noting at this point, that a typical furnace of similar capability would be much larger. Every effort has been made to keep it compact as possible since it will be mobile and takes from our usable print area.

Also, the connection contacts to the rods where the weakest point in wiring system, so we painstakingly tapped out each end of the SiC rod to accept 3/8″ stainless steel bolts. This alone will allow our cool ends to operate much much cooler, and since it eliminated the need for connection clamps, it doubled the length of undersized cold ends. Win/Win!

While it took tremendous effort to completely rewire our furnace, I am hopeful that it should last the life of the SiC heater rods themselves which are designed for many thousands of hours of operation. So I hope we don’t have to take it apart again anytime soon.

Leave a Reply